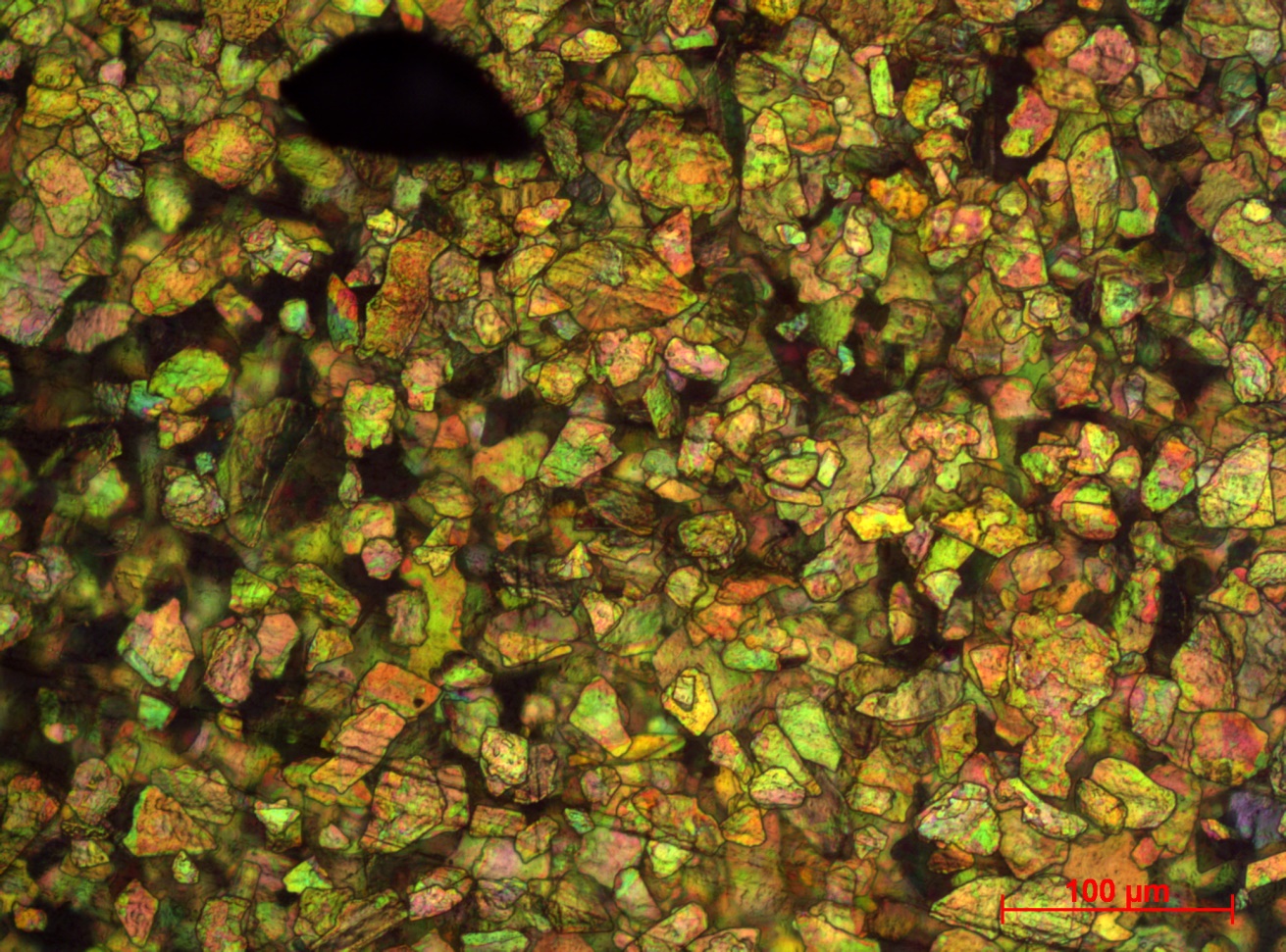

Modern paint systems have a wide range of functions that go far beyond corrosion protection. For instance, the perceived value of various everyday objects, such as motor vehicles, is often largely based on the optical appearance of their visible surfaces. The desire for a very high-quality appearance explains the success of effect pigments, which can be optimally embedded into complex polymer paint coatings and combined with high-gloss and sparkle effects in order to create the desired color impression. In addition to the optical characteristics of these effect pigments, their functional properties – such as electrical conductivity, reflectivity in the IR range, laser marking ability and weather resistance – are a major focus of the development process. The “Optical Materials and Technologies” division has used nanostructure-based diagnostic processes to study effect pigments, simultaneously with their development and production, for more than 20 years.

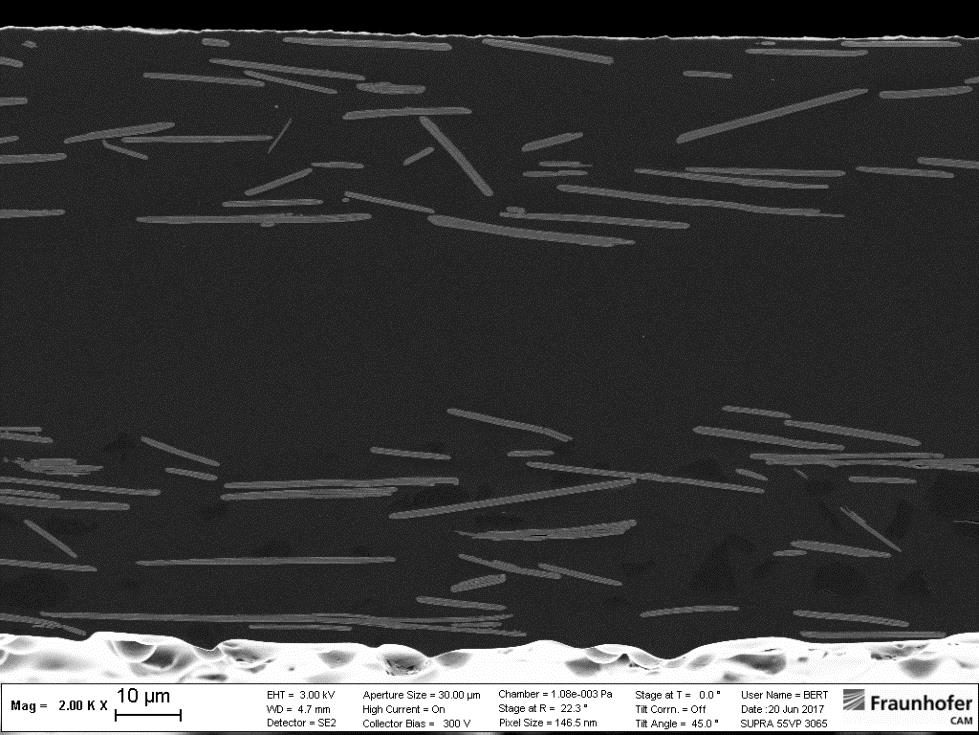

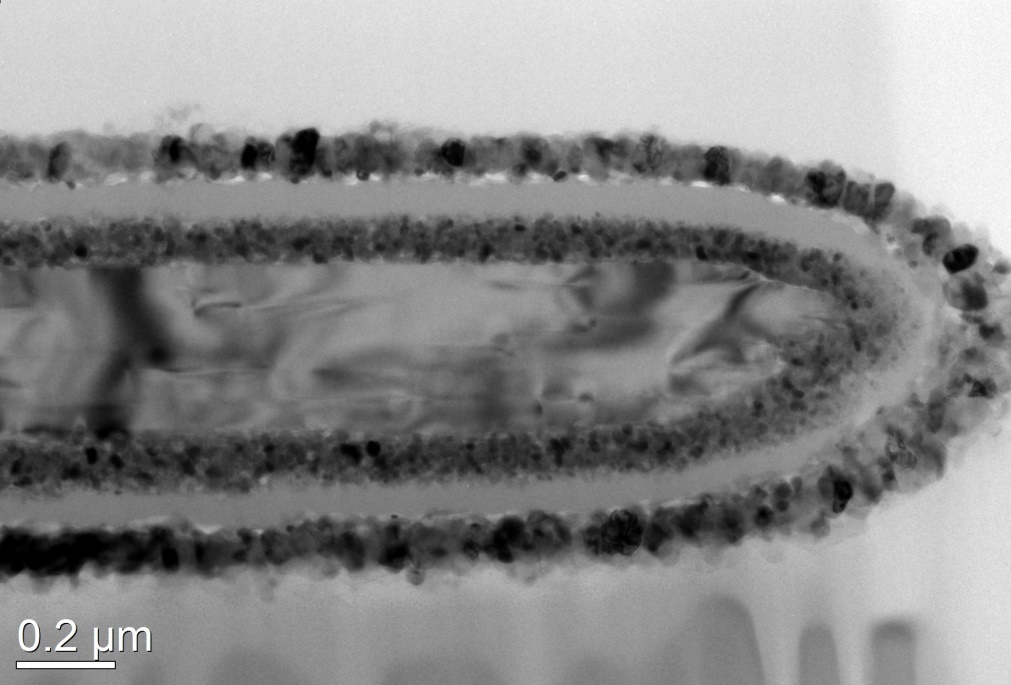

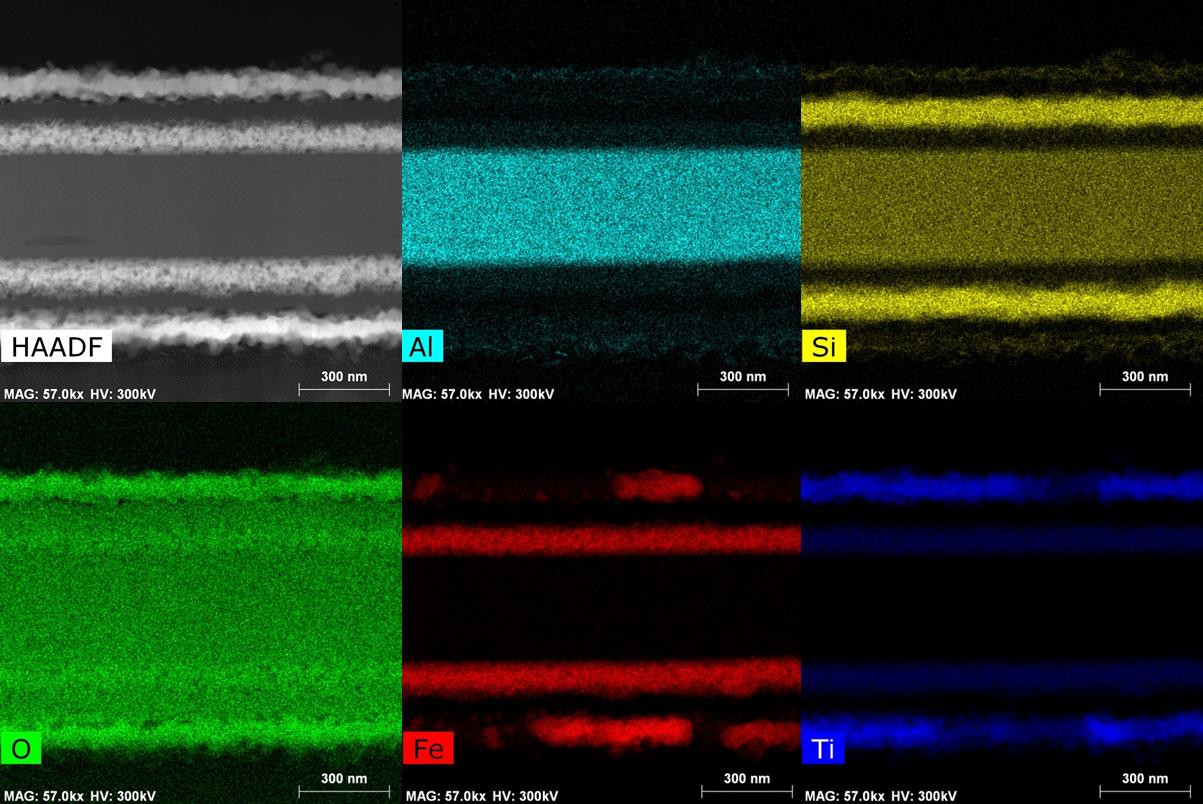

In designing effect pigments, interference layer systems are applied to a substrate particle whose composition and sublayer thicknesses define the optical appearance. These platelet-shaped particles typically have a diameter of several micrometers; they are a few hundred nm thick and are surrounded by layer systems made from individual layers that are just a few nanometers thick.

When it comes to developing and monitoring the production of these materials, the question often arises: how can such small objects be prepared, free from artifacts, so they can be studied as a cross-section? And what are the values of the various physical parameters, such as surface and boundary layer roughness, element distribution and layer thicknesses? Are the coatings crystalline or amorphous, and what kind of layer homogeneity do they have? What particle sizes are present? Are there any interactions between the layers? How well do the layers adhere to one another? And how do microstructural parameters affect the macroscopic optical appearance of the paint system?