Together with the Otto Schott Institute in Jena, an innovative, low-expansion glass ceramics method was developed – the first of its kind, 50 years after Zerodur, Ceran & Co.

Glass ceramics are often used as materials without significant thermal expansion. These are particularly resistant to thermal shock and do not change their shape even when temperatures fluctuate. Therefore, they are used for example for glass ceramic cooker tops, telescopic mirrors or mirrors for lithography. In principle, such glass ceramics are simple to produce. Finely distributed crystals with negative thermal expansion are produced in a glass that has positive thermal expansion: in the end this results in a zero to low expansion material. The main problem, however, is the production of suitable crystals with negative thermal expansion. The latter are traditionally based on high-melting lithium-aluminum silicates. Other crystalline phases with negative thermal expansion, which can be crystallized from silicate glasses, are hitherto unknown.

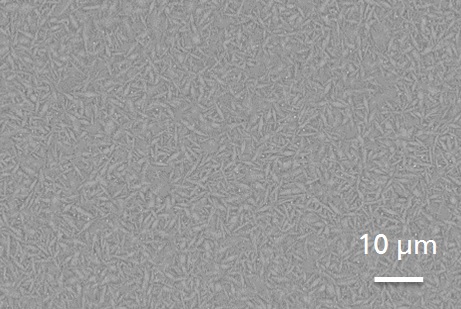

In the course of our research, a new crystalline material with the composition Ba1-xSrxZn2Si2O7 and with just this rare property was found. This is the first new negative-expanding silicate for 50 years. It is of great advantage that expansion conduct can be set variably to wide ranges of temperature. The crystallization conduct of this new glass ceramic had to be completely re-explored in recent years with the aim to separate the smallest possible and most finely distributed crystals in the glass. To prevent the formation of micro-cracks, which deteriorate mechanical properties, microscopically small crystals must be produced, which are finely distributed in the volume. Nucleating agents are needed for this, which separate the smallest of crystals from the glass volume when heat-treated. The crystals actually required can then grow on these extremely small seed crystals. Conventionally common nucleating agents such as ZrO2 or TiO2 do not work, however, in the new glass system, so that a combination, suitable in practice, could only be identified after two-dozen nucleating agent systems had been screened. Here, the use of high-resolution microstructure analyses in the development project (for example analytic transmission electron microscopy) greatly speeded up the optimization work, so that ultimately in a period of just one and a half years of development a material could be produced, which is suitable for practical application.

Thanks to the induction melting and tempering systems available at Fraunhofer IMWS, LEAZitTM glass ceramics can be adapted individually to required property profiles.