Reliable long-term data storage thanks to optimized microfilms

The long-term archiving of important economic and, above all, culturally and historically significant data is still preferably carried out using analog microfilms today. However, these can be damaged over time by biochemical changes and microbiological influences. Within a joint research project, the Fraunhofer Institute for Microstructure of Materials and Systems IMWS and FilmoTec GmbH Bitterfeld-Wolfen want to use a new technology to optimize the surface quality of the individual microfilm layers for prolonged durability. The aim is to establish significantly greater long-term stability and previously unattained photographic properties for microfilms.

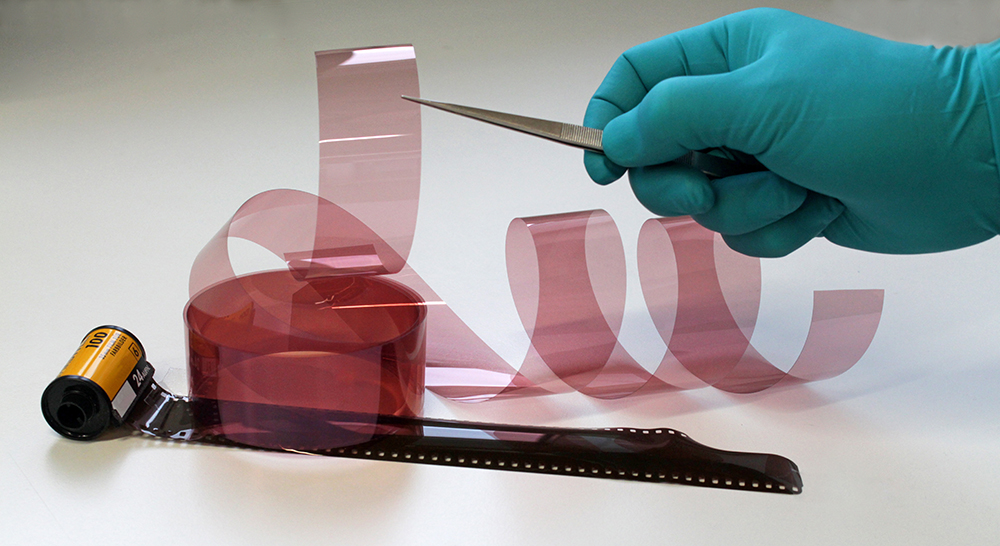

Digital storage media such as CDs, DVDs, and USB devices are still short-lived. Data stored on this type of carrier media may no longer be readable within just a few years due to the low durability of the media and constant rapid technological development, or must be converted to other data processing systems every three to five years at great expense and with high data losses. As a result of this, the long-term archiving of sensitive data still preferably takes place today using other media. Microfilms based on silver halide are used particularly often as a backup. These are rolls of film rolled up on a spool, which contain significantly scaled-down analog images of information such as texts, photos, and drawings. Microfilms have excellent long-term stability independently of technological developments and complicated property rights for servers and have a service life of several hundred years if they are stored under certain temperature and humidity conditions. They also support the storage of both analog and digital data and are completely forgery-proof.

For successful long-term storage, the films must also be resistant to any possible mechanical, chemical and biochemical environmental influences. The films consist of a 100 μm thick transparent film base made from polyethylene terephthalate (PET) with a 10-15 μm emulsion layer containing several layers of silver halide. The emulsion layer is bordered at the top by a gelatin protective layer and can be enclosed at the bottom using an anti-halo layer. However, these different wafer-thin layers can also be susceptible to faults: they can become detached from each other or be damaged by microbiological changes. It is also possible for the individual layers to be affixed to each other, which can lead to the destruction of the films and thus to data loss if they are separated.

The Fraunhofer IMWS is conducting research and development work together with FilmoTec GmbH in order to significantly improve the long-term stability of microfilms. The emulsion layers are equipped with environmentally compatible biocides to prolong service life. In addition, the surface of the PET substrate is modified by atmospheric plasma treatment with added nitrogen-based adhesion promoters. This could significantly improve the adhesion of the emulsion layers.

“We want to equip the gelatin layers of the films with suitable antimicrobial substances such as essential oils, which are harmless to humans. This would enable us to prevent biochemical attacks and material destruction caused by microorganisms,” says Dr. Ulrike Hirsch, project manager at the Fraunhofer IMWS. “Among other things, we are striving to replace the frequently used biocide phenol as it is a significant skin-irritant and is classified as hazardous to health,” continues Hirsch.

The photographic properties of the films must not be impaired here. Extensive morphological, chemical and mechanical investigations are being carried out in order to adequately assess the materials developed with regard to their use.

Following the research project, the technologies developed will be converted into new products in collaboration with FilmoTec GmbH: the aim is to produce microfilms that, in addition to very good durability, display previously unattained properties in terms of storage capacity, sharpness and resolution. The current state of the art is a pixel size of 6x6 μm, which can be exposed and read in four levels of grey. A new storage medium based on silver halide that is capable of recording structures in the 3x3 μm range in up to 16 different levels of grey is set to be developed as part of the project.