Quality testing and material development: Fraunhofer IMWS supports the fight against the coronavirus pandemic

The Fraunhofer Institute for Microstructure of Materials and Systems IMWS is supporting the fight against the COVID-19 pandemic with its expertise in the field of materials. The institute is currently working on the development of novel protective textiles in cooperation with nine other Fraunhofer Institutes across Germany. Innovative protection approaches are being pursued along with the optimization of wearing comfort. The research institution previously assisted clinical centers and the crisis management group of the city of Halle (Saale) in the spring.

“Making a contribution to overcoming the COVID-19 pandemic with our expertise and capacities is important to us. That is why we have been supporting the development of suitable protective materials since the first coronavirus cases emerged. We want to help people who are at particularly high risk, thereby alleviating the effects of this crisis,” says Prof. Matthias Petzold, acting Head of Fraunhofer IMWS.

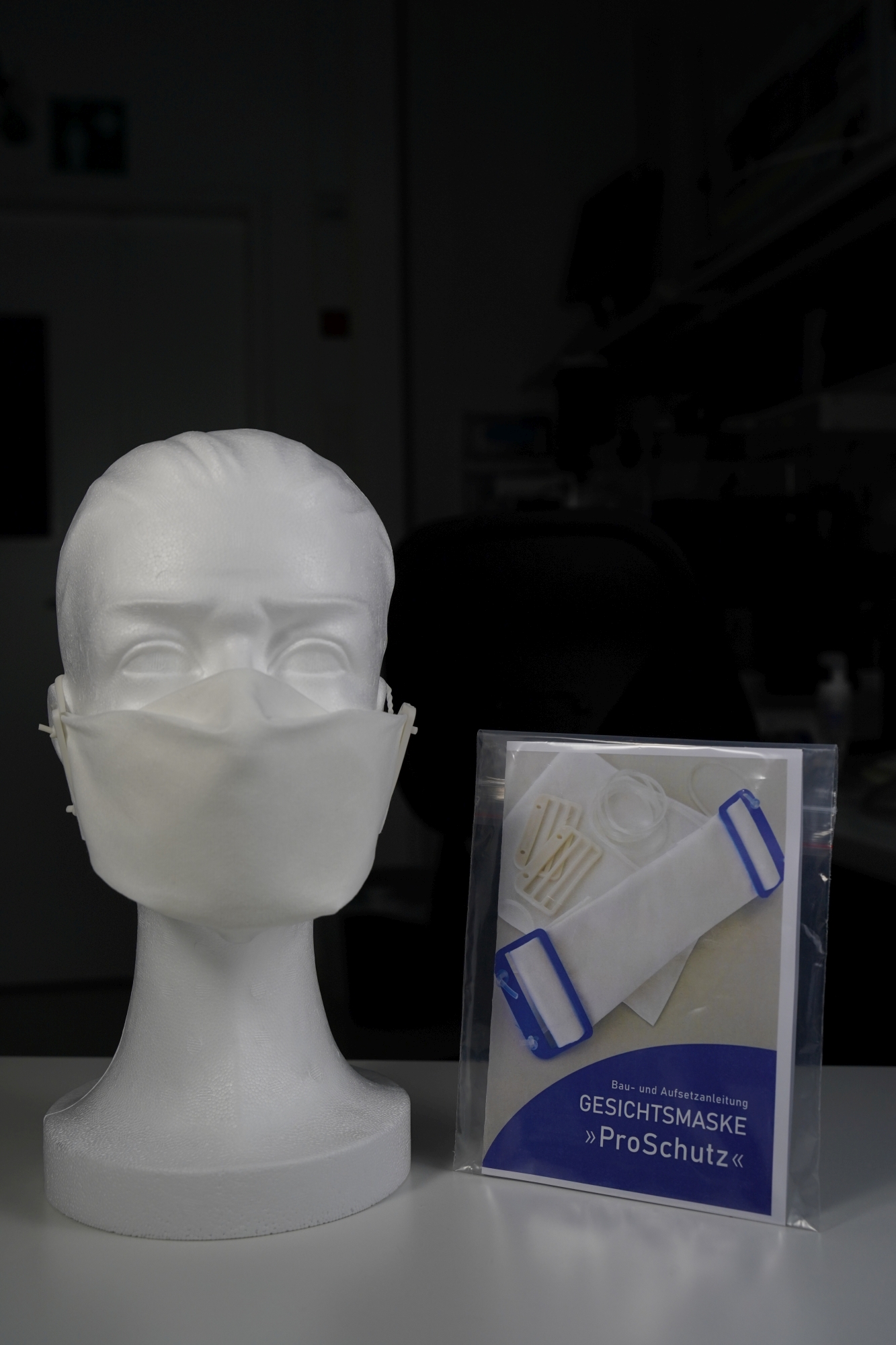

The institute specializing in material research with around 300 employees is pursuing various projects and approaches. During the first wave of infections in the spring, scientists at Fraunhofer IMWS tested various cloth masks for the crisis management group of the city of Halle (Saale). These semi-professional face masks were fabricated in local textile workshops. The institute also developed and produced filter holders for breathing masks, which were distributed through a cooperation partner. Reusable cloths with different filter effects can be inserted into the plastic holder. In cooperation with the Halle University Hospital and Merseburg University, the experts at Fraunhofer IMWS studied methods for the production of protective equipment for medical personnel, for instance using 3D printing.

They worked especially closely with the St. Elisabeth and St. Barbara hospitals in Halle to determine the actual demand in clinical centers and to test innovative approaches in practice. “We spontaneously developed many good ideas that were implemented with flexibility, especially in the first acute phase of the pandemic when there was an actual or looming shortage of protective equipment such as surgical masks or disposable gowns. Numerous starting points for promising further development emerged from these efforts. We now intend to pursue these together,” says Dr. Sven Seeger, head physician in the hospital's obstetrics clinic.

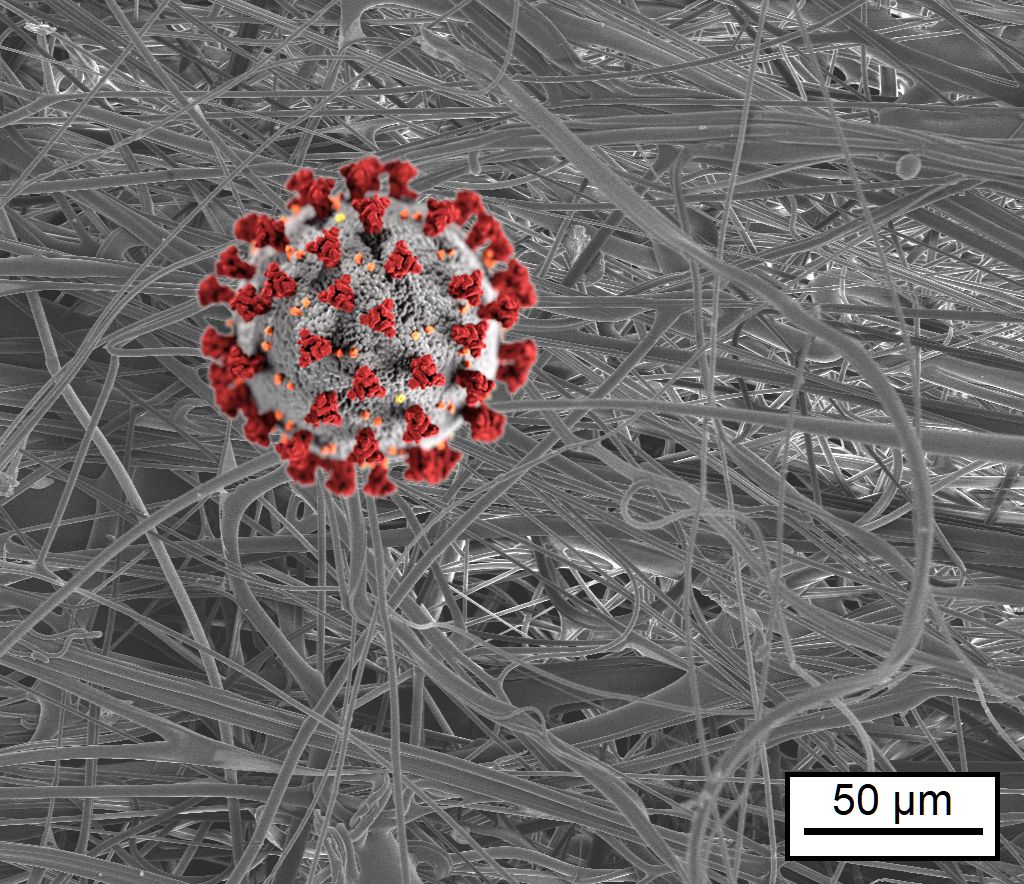

Intensive discussions in the course of this collaboration and with partners clearly showed that optimized protective equipment is needed to protect medical personnel and people in poor health against infection during the pandemic. Such protective equipment has to offer a high level of wearing comfort (low breathing resistance, long period of use) and provide an effective barrier against pathogenic germs. Fraunhofer IMWS wants to meet this demand in a joint project with other Fraunhofer Institutes launched in November to develop and evaluate new antiviral protective textiles.

“We want to lay the foundation for better solutions, especially to protect heavily exposed occupational and risk groups, but also for possible future pandemics. Our expertise in the assessment of materials is brought to bear here in particular,” says Dr. Christian Schmelzer, Head of the “Biological and Macromolecular Materials” business unit at Fraunhofer IMWS. “We developed a lot of additional expertise for new material diagnostics problems in a very short time, and also determined that the currently established test methods are not always suitable for the rapid, function and application case oriented characterization of material or functional properties during a pandemic. We are therefore developing new methods as well in addition to improved materials.” These include, for example, the evaluation of sterilization processes, new methods for the modification of materials using coatings, and the use of laser scattering measurement, acoustic microscopy, and 3D fluorescence microscopy for the evaluation of optimal functioning as well as safety and health requirements of protective textiles.

Aside from Fraunhofer IMWS, numerous other Fraunhofer Institutes across Germany with their technology know-how are developing supporting measures to overcome the pandemic in the “Fraunhofer vs. Corona” program.