Fraunhofer CSP develops a filtration system for better data analysis of microplastics in bodies of water

Microplastic particles in the water are a growing problem for the environment. The Fraunhofer Center for Silicon Photovoltaics (CSP) is working with partners to develop a new filtration system that makes it faster and easier to measure water pollution. The research project, led by the Federal Institute for Materials Research and Testing (BAM), hopes to create a database that can be used to analyze and ultimately reduce water pollution.

The introduction of microplastic particles – in other words, plastic particles smaller than 1 millimeter – into our ecosystem is becoming increasingly problematic. But how do microplastics end up in bodies of water and wastewater? And how can they be studied and documented in those places? There is currently no reliable scientific database covering the sources, incidence and effects of microplastic particles on the environment.

The research project “Representative Investigation Strategies for an Integrative Systemic Understanding of Specific Introductions of Plastics Into the Environment (RUSEKU),” which was initiated by the Federal Institute for Materials Research and Testing (BAM), hopes to develop a testing procedure by 2021 that can be used to measure particle introductions into bodies of water more quickly and uniformly. It can also be used to determine which bodies of water have a particularly high concentration of microplastics.

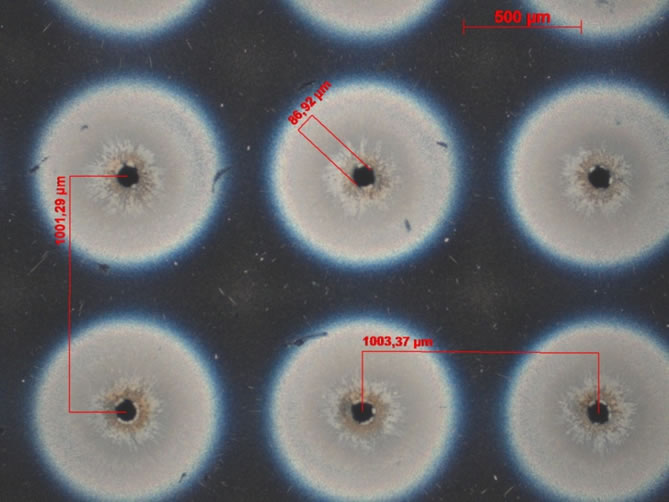

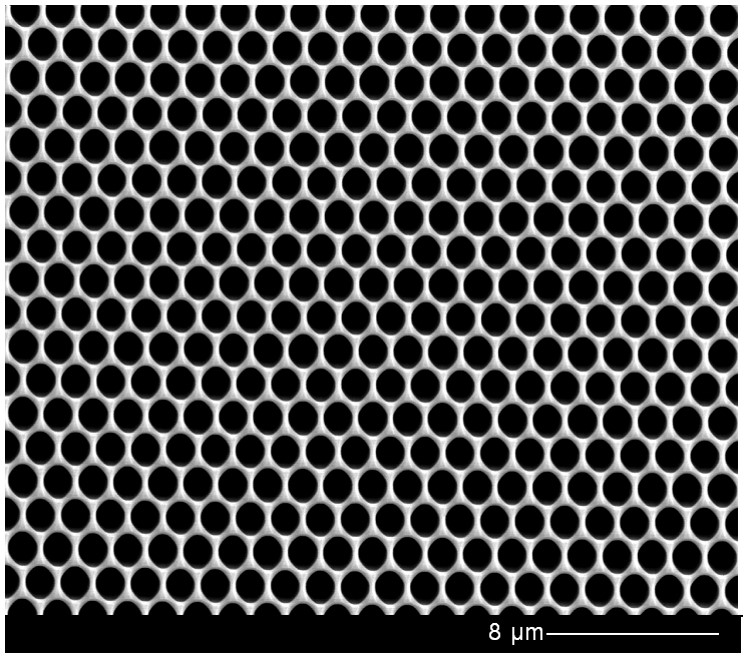

As part of this joint research project, the Fraunhofer Center for Silicon Photovoltaics (CSP) is working with SmartMembranes GmbH to develop a special filtration system that will form an important part of a uniform and uncomplicated sampling procedure. The cascade filtration system will use special silicon filters with defined hole frequencies and hole sizes to capture the plastic particles.

“The sampling method is very important for assessing the quantities of microplastics in our groundwater, drinking water and wastewater as well as surface water. We are planning to create a kind of sampling kit that will make it much easier,” says Dr. Christian Hagendorf, a researcher at the Fraunhofer CSP and one of the people responsible for the research project.

“We will use lasers and chemical etching processes to cut the right size holes into a silicon carrier that retains the particles. When we analyze them later in the lab, we can take advantage of the chemical composition of silicon, which is transparent in the transmission process within a wide wavelength range of infrared light and makes the microplastic particles visible to the spectroscopic measurement technology,” continues Hagendorf.

Another important parameter for the quality of the filters is their mechanical stability; load conditions caused by water currents during the sampling process cannot cause the filters to break. In addition, the filters must have “smart,” optimized hole geometry and surface characteristics. Another goal of the project is working with the partners to define a prescribed workflow, from sampling to purification to analyzing the microplastic particles. “Smart sampling” will perfectly coordinate the process of documenting microplastics, from sampling to fast analytics.

The resulting procedure for efficient, reliable microplastic sampling will offer a basis for strategies and regulations that can help reduce microplastic levels in the water cycle. The joint research project is supported by the Federal Ministry of Education and Research (BMBF) and is part of the main research area “Plastics in the Environment.” In addition to the Fraunhofer CPS, six other scientific institutions and three medium-sized companies are also taking part in the project.