Fraunhofer IMWS develops test methods for electronic protective housings

Plastic housings, such as those used in wind turbines, are extremely important for protecting built-in electronics. However, these insulation systems are often exposed to extreme weather conditions and electrical fields. The Fraunhofer Institute for Microstructure of Materials and Systems IMWS, together with 3P GmbH, has developed an innovative testing concept that makes it possible to investigate the causes of material defects under operating conditions. The project won an award at the International Conference on Integrated Power Electronics Systems.

Power electronics components, such as inverters in wind turbines, are subject to high levels of stress due to the various environmental conditions. Moisture, heat and strong electrical fields can have a negative impact on sensitive electronic components or lead to their complete failure. To ensure optimum conditions for the electronics, they are shielded from environmental influences by protective housings. More accurate failure predictions for the protective housing materials are now possible using an innovative test sample design for engineering plastics developed by Fraunhofer IMWS together with Präzisions-Plastic-Produkte GmbH (3P GmbH). Insulation materials can thus be tested in the electric field under different environmental conditions over a prolonged period of time.

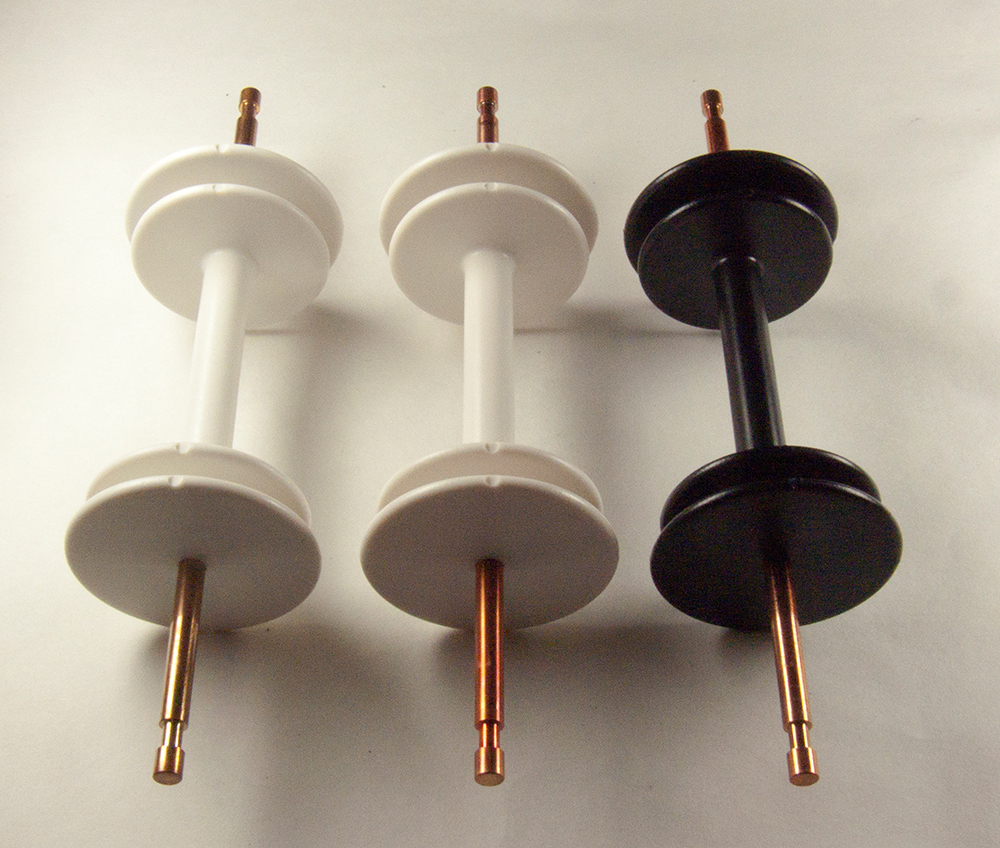

In order to develop the test concept, the scientists made test specimens from PBT (polybutylene terephthalate) plastics using injection molding. One material sample was reinforced with glass beads, while the other two were reinforced with glass fibers. The test specimens each consisted of two electrodes that were injected directly into the plastic material so that no additional insulation was required.

The investigations led to a better understanding of failure processes, particularly with regard to the influence of moisture. In addition, the Fraunhofer IMWS and 3P GmbH have developed new methods of detecting defects and making long-term predictions regarding defect formation. “The new test method makes it possible to develop new materials for housings and optimized processing technologies so that even higher-quality and more efficient housings are available for inverters in wind turbines and car transmissions,” says Sandy Klengel, group leader at Fraunhofer IMWS. “The quality and service life of the housings are becoming increasingly important because the trend towards the miniaturization of electronic assemblies is also increasing the demands on insulation systems.”

Further research is needed in order to make more precise statements about the material degradation, service life properties and aging mechanisms of plastics. Future studies should also consider the influence of additives such as flame retardants in order to optimize material composition.

The Fraunhofer IMWS presented these results together with 3P GmbH at CIPS 2018 (International Conference on Integrated Power Electronics Systems) and won the Best Poster Award for its presentation of the test concept.

The research project was funded by the European Regional Development Fund Saxony-Anhalt and the European ECPE Network through the Joint Research Program in cooperation with the University of Kassel.