Fraunhofer IMWS further develops lightweight technology using thermoplastic honeycomb cores

Lightweight components such as fiber-reinforced plastics play an essential role particularly in automotive construction. Lighter materials help reduce carbon dioxide emissions. In a research project, the Fraunhofer Institute for Microstructure of Materials and Systems IMWS and ThermHex Waben GmbH are working to manufacture lightweight components with integrated thermoplastic honeycomb cores, using a hybrid injection molding process, that are designed for automotive applications. The two partners have been working together on this issue since late 2015; in the new project, they will develop an innovative technology for large-scale production of hybrid organosandwich components for structural applications.

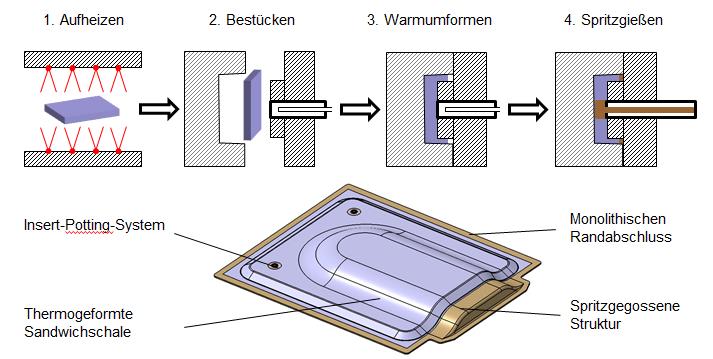

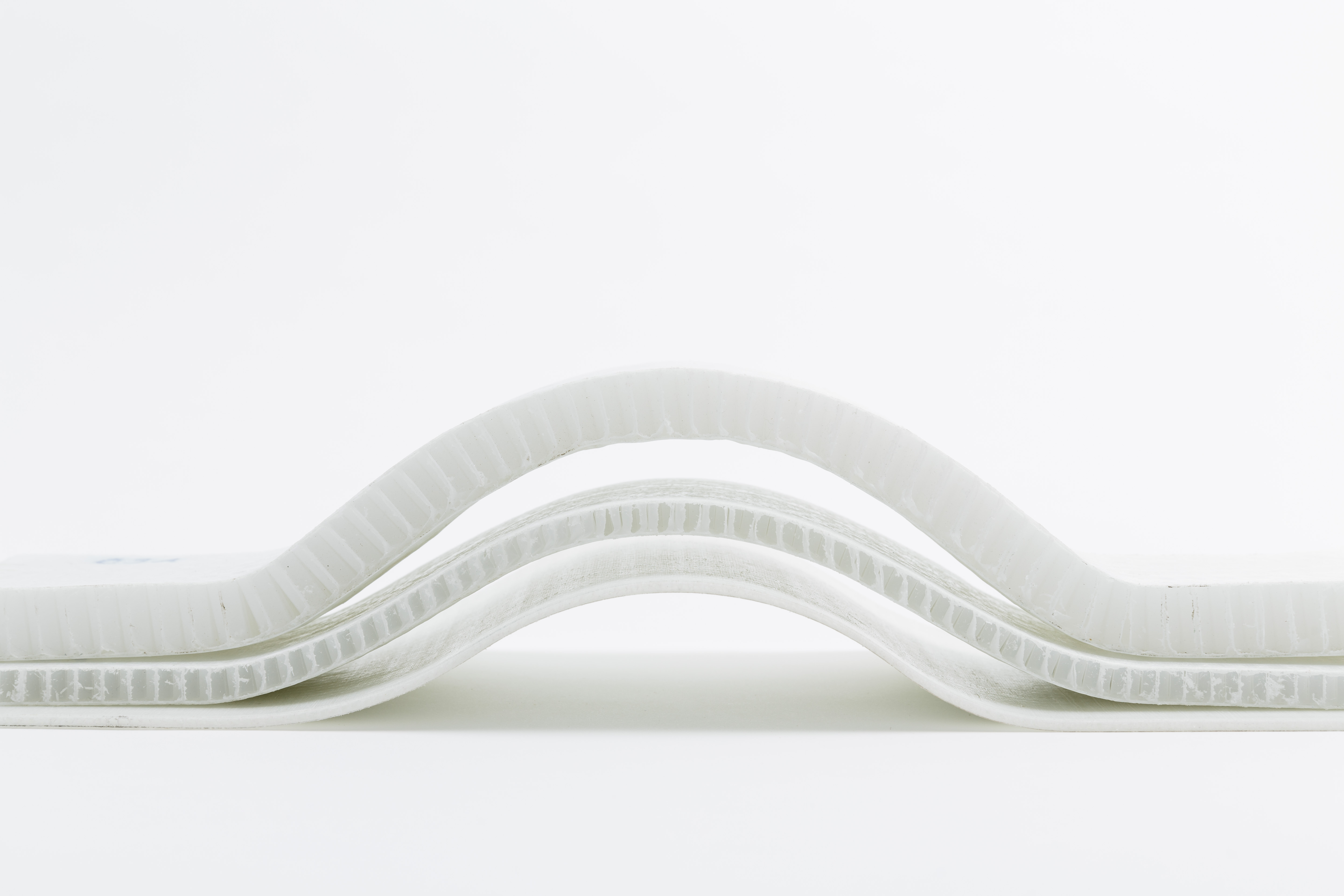

In the previous project, the Fraunhofer IMWS and ThermHex focused on the material and process-related foundations for manufacturing and processing semi-finished organic-sheeting sandwich products. Now, in another collaboration, they will use the knowledge they have gained to turn the technological process steps into an organosandwich technology. Using the semi-finished organic-sheeting sandwich products, hot forming and injection of functional elements in a hybrid injection molding process will produce an exploitation-ready, functionalized component – in an optimized process that is both large-scale compatible and cost-effective. Semi-finished organic-sheeting sandwich products are named for their layered quality: sandwiched between two very thin layers of thermoplastic fiber composites (organic sheeting), there is a thermoplastic honeycomb core. This design, which does not require additional reinforcement ribs, provides good component rigidity with minimal weight. Cost effectiveness can be optimized if the semi-finished products are continuously applied and fixed to the honeycomb core using an inline process.

Here the project partners are concentrating on applications for the automotive industry. This creates special requirements for the temperature resistance of the semi-finished products, so the material basis will also be expanded. In addition to polypropylene (PP), the experts will also include polyamide 6 (PA6) as well as polyethylene terephthalate (PET) and recycled PET as a sustainable thermoplastic matrix material, and study them in terms of how well they can be processed.

“In addition to developing the technology and expanding the material basis, we want to model the process steps and the structural-mechanical behavior in order to understand how the individual steps influence the application behavior of the finished component,” says Dr.-Ing. Ralf Schlimper, Project Manager at the Fraunhofer IMWS. The main focus is on how they influence the internal honeycomb structure and on any changes during hot forming, since that determines the behavior and reliability of the finished component – and thus also the possibilities for industrial applications.