In view of raw material shortages and ecological aspects, biobased composites made from regenerative natural materials and polymers, for example, wood-polymer composites, are becoming more important. However, such components made of plastic composites are often more susceptible than components made of metallic or inorganic construction materials. Deformation occurs under continuous loading – the material is said to creep. If it is then loaded again, a certain deformation remains stored in the component. Under continuous deformation due to creep, substantial damage in the form of cracks and fractures can occur, which ultimately lead to failure of the component. A project at the Fraunhofer IMWS is searching for solutions to make biobased composites more resistant. In a project that will continue until the end of December 2017, researchers at the Fraunhofer IMWS are working with NOVO-TECH GmbH & Co. KG in Aschersleben, Saxony-Anhalt on a formula that predicts the performance of wood-polymer materials, in order to optimize load-bearing structures.

In a project that will continue until the end of December 2017, researchers at the Fraunhofer IMWS are working with NOVO-TECH GmbH & Co. KG in Aschersleben, Saxony-Anhalt on a formula that predicts the performance of wood-polymer materials, in order to optimize load-bearing structures.

NOVO-TECH GmbH & Co. KG produces extrusion profiles from wood-polymer composites. With its individual material composition GCC (German Compact Composite) it is the market leader and has specialized in WPC products (Wood Polymer Composite). Structural components are made of composite plastics with natural fiber polymer materials, which are used indoors and outdoors in the form of patio and privacy protection systems, loading floors and in formwork for the production of concrete elements.

At the heart of the project is the production of high-quality materials made from biomass as part of a bioeconomy. »Biobased composites are an important future technology with regard to the use of sustainable resources. The demand for scientifically based solutions for understanding the mechanics and the detailed processes that occur during their use is thus increasing«, said Thomas Hanke, project manager at the Fraunhofer IMWS.

The aim of the research project is to develop a component safety concept, which predicts long-term creep behavior. To do this, the relevant failure mechanisms for load-bearing components made of GCC (German Compact Composite) must be determined with regard to their long-term and deformation behavior through to fracture.

To obtain relevant results, the researchers first examined the material characteristics and use-induced scatter in sample components from short and long-term tests; this data are input into models, from which the virtual life of the materials can be derived.

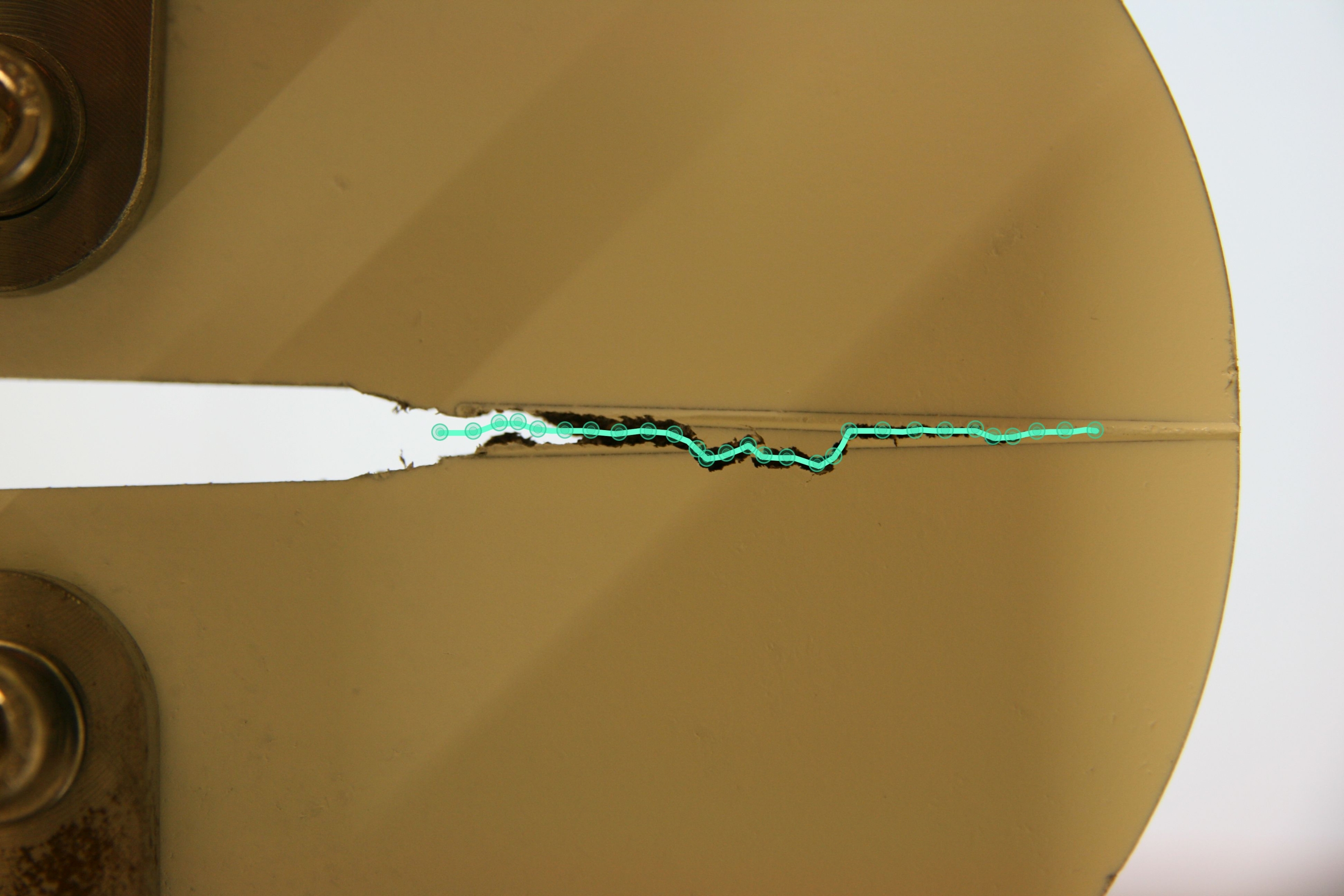

Scientifically assured simulations of the material behavior allow forecasts to be made for periods of between five and ten years, in order to produce components that are safer and are durable for longer in future. To determine the material properties of load-bearing components, a round compact tension test (RCTT) was developed at the Fraunhofer IMWS. With the help of the RCT sample, the breaking tenacity (fracture toughness) of a material can be determined. A sample is deformed in a mechanical or servohydraulic test machine until it fails. The maximum continuously measured force and the crack length are used to determine a so-called critical stress intensity factory. If the crack growth parameters are also derived from the results, a life model can be developed.

If the mechanisms that lead to failure of the component have been examined sufficiently, the defined limit states or damage models can be used to optimally design components according to the performance of the underlying material.

»By trying out new material concepts, we not only secure new knowledge in the field of plastics engineering and bioeconomy. Our methods and models can also be usable for other innovative, highly-filled biobased materials. In this way we make an important contribution to implementation of the regional innovation strategy goals of the State of Saxony-Anhalt«, is how Thomas Hanke assessed the project.