3D printing with fiber-reinforced plastics designed for load paths

Automation, Sonder- und Werkzeugmaschinen GmbH (ASW), the Forschungs- und Beratungszentrum e.V. (FBZ), an affiliated institute of Merseburg University of Applied Sciences, and the Fraunhofer Institute for Microstructure of Materials and Systems (IMWS) are looking to develop new areas of application for plastic-based and fiber-reinforced 3D printing through a cooperative project. They focus on an innovative manufacturing technology that aims to produce light and stable components with complex geometry without expensive tooling. Such solutions are in demand above all for robust plastic components in small and medium quantities.

In the project, which is scheduled to run for two years, the competencies of ASW in the field of plant and mechanical engineering, the extensive experience in additive manufacturing at the FBZ and the expertise of the Fraunhofer IMWS in reinforced polymer materials and corresponding processing methods will be combined in order to break two of the limits that currently exist in the booming field of 3D printing. First, the use of fiber-reinforced plastics in additive manufacturing processes is still not very widespread. This approach, through the integration of high-stiffness and high-strength fiber systems made of, for example, glass or carbon, can enable very good mechanical properties that are often not yet achieved with current 3D printing processes.

Secondly, in order for additive manufacturing processes for prototyping, individual or small-batch production to be introduced on a broad industrial scale, the manufacturing flexibility, manufacturing efficiency and resulting component properties must first be substantially improved. The approach taken by the project partners is trajectory-based manufacturing of 3D printed parts using the Fused Filament Fabrication (FFF) process. The print head moves along previously defined trajectories.

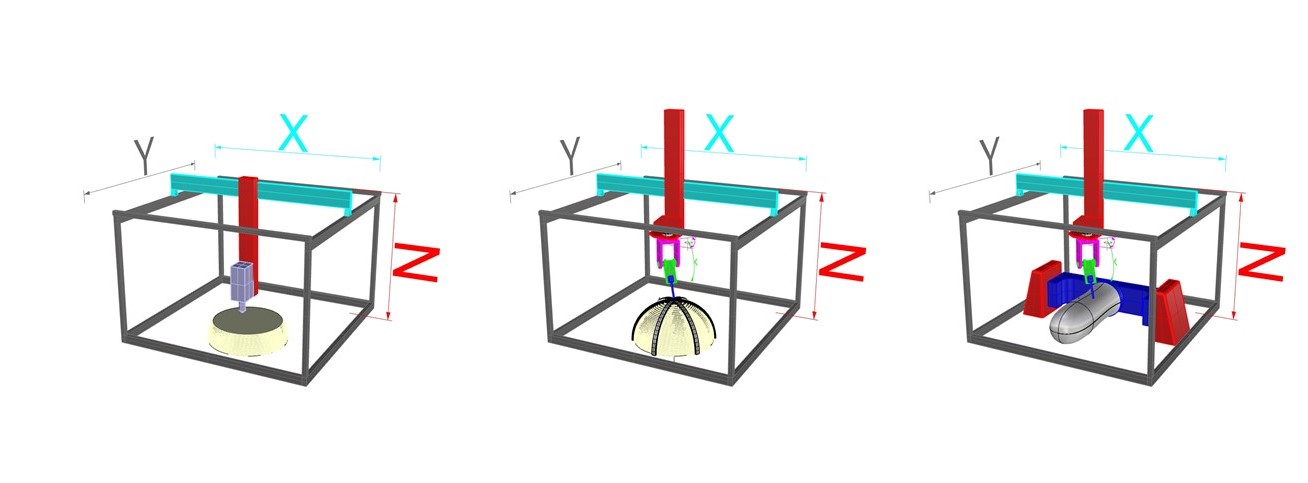

One particular advantage that this idea has: In 3D printing, the components are usually created using a layered structure. The print head moves along an X and Y axis and creates a plane of the desired component. Then the next plane is placed over it. The connection between the individual planes (Z axis) is often comparatively weak and reduces the mechanical properties in this direction. This problem could be solved with trajectory-based generative manufacturing. Furthermore: The pressure filaments could be adapted to the relevant load paths and deposited fully three-dimensionally in the component by strengthening the highly stressed areas of the subsequent component. In conjunction with advanced fiber-reinforced 3D printing materials, the mechanical load-bearing capacity was significantly increased, enabling the generation of lightweight fiber-composite components that can be used in real applications and are capable of withstanding high stresses.

The project partners therefore intend to set up a test facility with a 6-axis portal system that enables free movement of the 3D print head within space and thus arbitrary trajectories of movement. The filament and fiber strands are to be placed on adapted support structures, which may have to be removed from the component at a later stage. Research is also being conducted into the combination of layered and trajectory-based 3D printing processes and the load-path-compatible design of highly stressed 3D printed components with short- and continuous-fiber-reinforced thermoplastics.

“Our aim is to combine the advantages of 3D printing processes, such as the high degree of design freedom, very short production times, the avoidance of cost-intensive tooling development and relatively low-cost plant engineering, with the outstanding mechanical properties of advanced fiber-reinforced composites. This means that in the future it will be possible to produce not only prototypical demonstrators, but also components for industrial use for individual and small series production, which can be customized to the specific application loads by means of fiber-composite compatible designs,” says Dr. Patrick Hirsch, project manager at the Fraunhofer IMWS.

This approach entails considerable changes along the entire process chain: It requires different printers, different data models, different software and a different mindset on the part of the designers when designing components. The “ink” must also be designed differently. The Brightlands Materials Center from the Netherlands is involved as an associated cooperation partner in the development of suitable filaments.

To develop the required solutions, the project partners are starting with a laboratory-scale pilot plant. The findings on feasibility and technical implementation are then transferred to a scaled test facility for research in an industry-oriented application environment. The novel 3D printing technology will be used to produce demonstrator components representing applications from the aerospace, automotive, mechanical engineering, medical technology and orthopedics sectors. These components are tested and evaluated, for instance with regard to material and component characteristics (e.g. dimensional accuracy, surface quality, mechanical performance, fiber orientation, fiber volume fraction, bonding and morphology of the individual layers). At the same time, further insights will be gained into the boundary conditions of the manufacturing process (e.g. temperature field in the vicinity of the print head) and the general functionality (e.g. precision of the movement kinematics).

“In addition to mastering the material properties, the development of the system concept, machine control concept and control software represent substantial challenges. We are confident, however, that we will be able to master them. This would constitute an enormous contribution to the improved prototype development of complex components as well as to the resource-efficient production of small series or highly individualized and customized individual products to meet specific customer requirements,” says Hirsch.

Once the project has been concluded, in which the process will be fundamentally researched and the plant concepts will be implemented and tested in the test facilities, the construction of a pilot plant at ASW is planned.