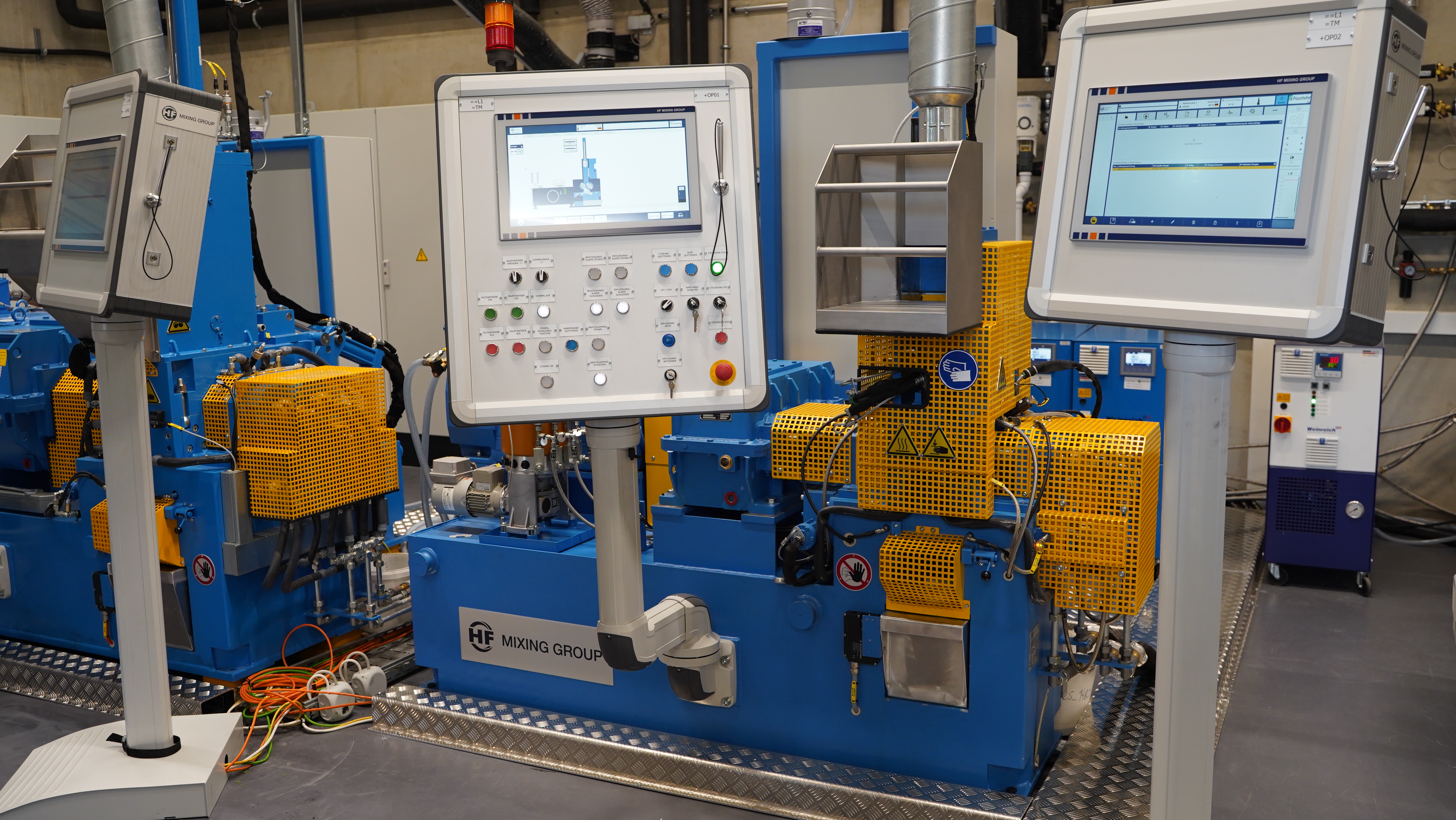

We work on issues regarding polymer processing and optimization of polymer materials. The aim of our work is to achieve improved energy and resource efficiency by using the materials and processes developed by us on an industrial scale. Our clients in the field of mobility applications, i.e. cars, aircraft and rail vehicles, profit from our work just as much as companies in the plastics or polymer industry and in mechanical engineering.

We supply solutions, for example, for thermoplastic-based lightweight construction, tyre applications or the use of bio-based polymers in high-volume production. We consider the entire value-adding chain, from the microstructure of the material through to the tailormade component. We develop on a small scale and, among other things, in the Fraunhofer Pilot Plant Center for Polymer Synthesis and Processing PAZ we have plants up to industrial scale and can carry out prototype mould validation.

Our know-how includes:

- Raw material selection

- Microstructure design

- Processing technology

- Characterization of material properties on a laboratory, test centre and pilot plant scale

- Analysis of component properties, including predicting their behavior in use

- Modelling and simulation

- Process development