The surface of plastics, metals and semiconductors is often selectively adjusted during the manufacturing process so that the materials are optimally suitable for a specific application. Processing with cold plasma is a particularly efficient method: Films treated with it can be printed on better, solar cells can convert incident sunlight into electricity better. Yet precisely what happens when cold plasma meets a film or solar cell? This is what researchers of the Fraunhofer IMWS want to find out in a new project. Their answers can help to optimize manufacturing processes and open up new fields of application.

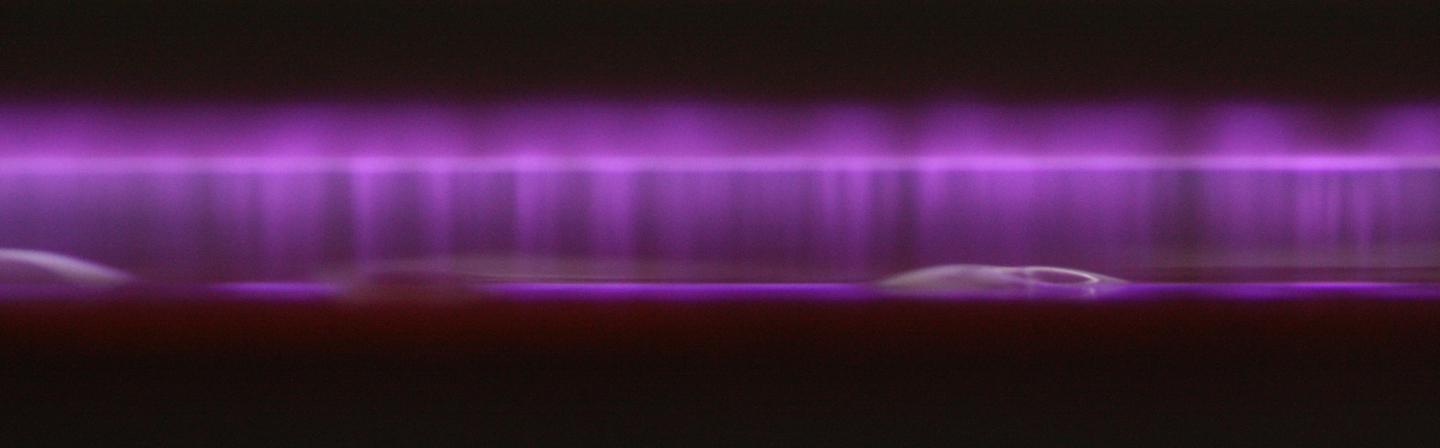

Plasma is the term used to describe electrically charged gas mixtures. Low-pressure plasma is already frequently used in industry. It is also called »cold plasma«: because only a small quantity is added to the gas mixture, only the electrons in it are set in motion, not the larger electrical charge carriers. If they were to also move the gas mixture would quickly become thousands of degrees hot. Producing such cold plasma at room temperature and atmospheric pressure has only been possible for around 20 years – the new technology has produced manifold new possible uses. Apart from the processing of plastics, solar cells or semi-conductor materials, low-pressure plasma is also used, for example, in medicine for wound treatment or in cancer therapy.

In its industrial use, manufacturers profit above all from the fast and manifold effect of plasma treatment. For example, changing the surface properties of a film requires a treatment time of less than one second. The method can be used to clean surfaces, for activation, etching/texturing or functionalizing/coating. Through activation, for example, the surface energy of the film can be increased, thus improving wetting with printing inks or adhesives.

One challenge that remains is getting the process to be consistent, because different factors such as pressure, climatic conditions, treatment duration, gas flow and the chemical composition of the gas mixture influence the effect of the plasma treatment, especially under atmospheric pressure. In addition, it would be advantageous to be able to more specifically define the achieved properties of the surface, for example, to develop a plasma treatment that brings about the precise desired properties with regard to adhesion, antistatic, anticondensation or antibacterial effect.

This is precisely where the »FlexPlas« project, due to run until October 2019, comes in and which is part of the Chemical and Biosystems Engineering Centre: The Fraunhofer researchers want to find out precisely what happens when the plasma comes into contact with the surface of a material. Which particles in the plasma bring about the decisive changes? How long do these changes remain stable? When does the process reach its optimum, before the properties begin to worsen again? Answers to these questions would enable improved process control, and more precise control of the chemical and morphological properties of the treated surfaces.

There is also a large demand for this in the photovoltaics sector. Here low-pressure plasma is used to remove organic molecule residues from the surface of solar cells or to passivate the surfaces, and thus protect them from undesirable corrosion. Another important field of application is texturing the silicon material from which the solar cells are made. On reaching the surface, the incidental sunlight is then steered by their special texture so that it can be converted into electricity better – the efficiency of the solar cells therefore increases. Plasma texturing offers large potential, especially for so-called »kerfless« wafers (which do not require the previously standard production and sawing of silicon blocks).

While the process window in the plasma treatment of films offers some leeway, the production of precisely defined textures on the surface of flexible wafers made of multicrystalline silicon is incomparably more difficult. Because the aim is to simultaneously optimize the optical and electrical properties. Precise control of the gas phase is therefore decisive to enable the method to be used cost effectively at a later stage in large-scale production.

To prepare the way for this, the researchers in Halle want to develop new methods of measurement, which plasma treatment processes can be improved significantly. In addition, diagnostics are to be established for the new type of plasma texturing of solar wafers, to enable monitoring the complex processes for use in mass production. During the plasma treatment process, optical and mass spectroscopic techniques are used to measure the composition of the gas mixture and the interactions between the individual particles in it. The aim is for the developed methods to be used later for process monitoring of industrial plants.