High efficiency and low production costs: These are the qualities with which thin-film solar modules are acquiring worldwide market shares. Modules based on cadmium telluride (CdTe) are particularly promising. Exhausting their potential and making it usable for production on an industrial scale is the objective of a joint project of the Fraunhofer CSP and Calyxo GmbH.

Around 90 percent of the photovoltaic systems installed worldwide operate with solar cells made of crystalline silicon. Thin film modules have numerous advantages: They are lighter, cope with shade better and deliver high yields in weak light conditions. There are also significant points in favour of thin-film photovoltaics in production: Energy and material consumption for their manufacturer is significantly lower, which cuts production costs and provides competitive values for the important ratio of costs to electricity yield even for small production quantities.

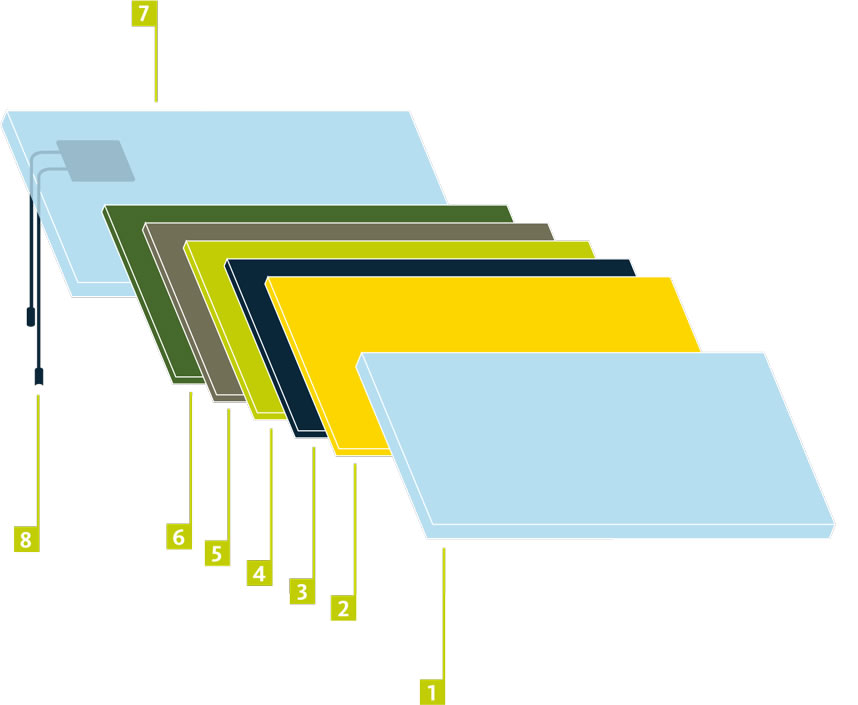

Calyxo GmbH has specialized in the production of such thin-film solar modules. Such modules are made up of several layers of photosensitive layers (films), which are only a few micrometres thick and are applied between a transparent front cover panel and a rear glass panel. The multi-layer stack of films is made by the sequential deposition of several individual films, which have different semiconductor properties that are matched with each other.

The company from Solar Valley near Bitterfeld mainly uses the new cadmium telluride technology. This has already proven its performance with regard to efficiency (> 18.7 percent) and cost efficiency (< 0.35 euro per Wp) on a laboratory scale. These record results were achieved by using new semiconductor materials. Together with the Fraunhofer CSP, this potential is now to be realized in a project that will continue until November 2017. The main lever is the use of new semiconductor thin-film stacks. To this end, fundamental and systematic research work is necessary: into semiconductor engineering, process engineering and for the subsequent implementation in the production of solar modules.

In addition to the new materials, the project partners also want to research, for example, innovative deposition and structuring methods. A new method of measurement is also to be tested.

»The efficiency of the solar cells is determined on the one hand by the structural and electronic properties of the different semiconductor films themselves. On the other hand there are electro-optical and electronic characteristics, which limit the efficiency, especially at the interfaces between the individual films. That’s where we want to start«, explains Dr. Volker Naumann, who is responsible for the project at the Fraunhofer CSP.

The films and interfaces are to be optimized through targeted development of individual process steps and accompanying semiconductor characterization in mini solar cells. Calyxo is responsible for the further technical development and adaptation of the deposition, activation and tempering processes for the new semiconductor materials, which takes place not only on a laboratory scale (on the equipment of the research line and in the research coating plant at the Fraunhofer CSP) but also along the existing production line of Calyxo. The Fraunhofer CSP will carry out the more in-depth characterization of the semiconductor materials and deducing parameters for production-related optimization.

»Through systematic experiments we will acquire a fundamental understanding of the film properties and find out what influence these properties have on the electrical-optical parameters of the solar module. Because the aim is to develop methods with which the film properties can be specifically adapted and how the films can be produced cost-effectively and suitable for mass production«, said Frank Becker from the Calyxo development department. If they succeed, the project partners expect a significant increase in efficiency of at least 3 percent absolute on a laboratory scale due to the optimized design of a new type of film stack for cadmium telluride solar cells. This would make an important contribution to increasing the market share of thin-film solar modules still further and thus strengthen cost-efficient electricity production from renewable energy.