The joint project "digitalTPC" has been running at the Fraunhofer IMWS since February 2019. What are the goals?

In the joint project "The digital twin for thermoplastic composite lightweight construction", or "digitalTPC" for short, we are developing a digital twin for thermoplastic composites together with three other Fraunhofer institutes. This is an exciting and new environment for us, not necessarily science- or engineering-based, but driven by data, IT and AI. With the approach of digitally mapping a complete value chain with a view to material and material changes, we are approaching a completely new interpretation of the term "digital twin".

What is special about your work on the project?

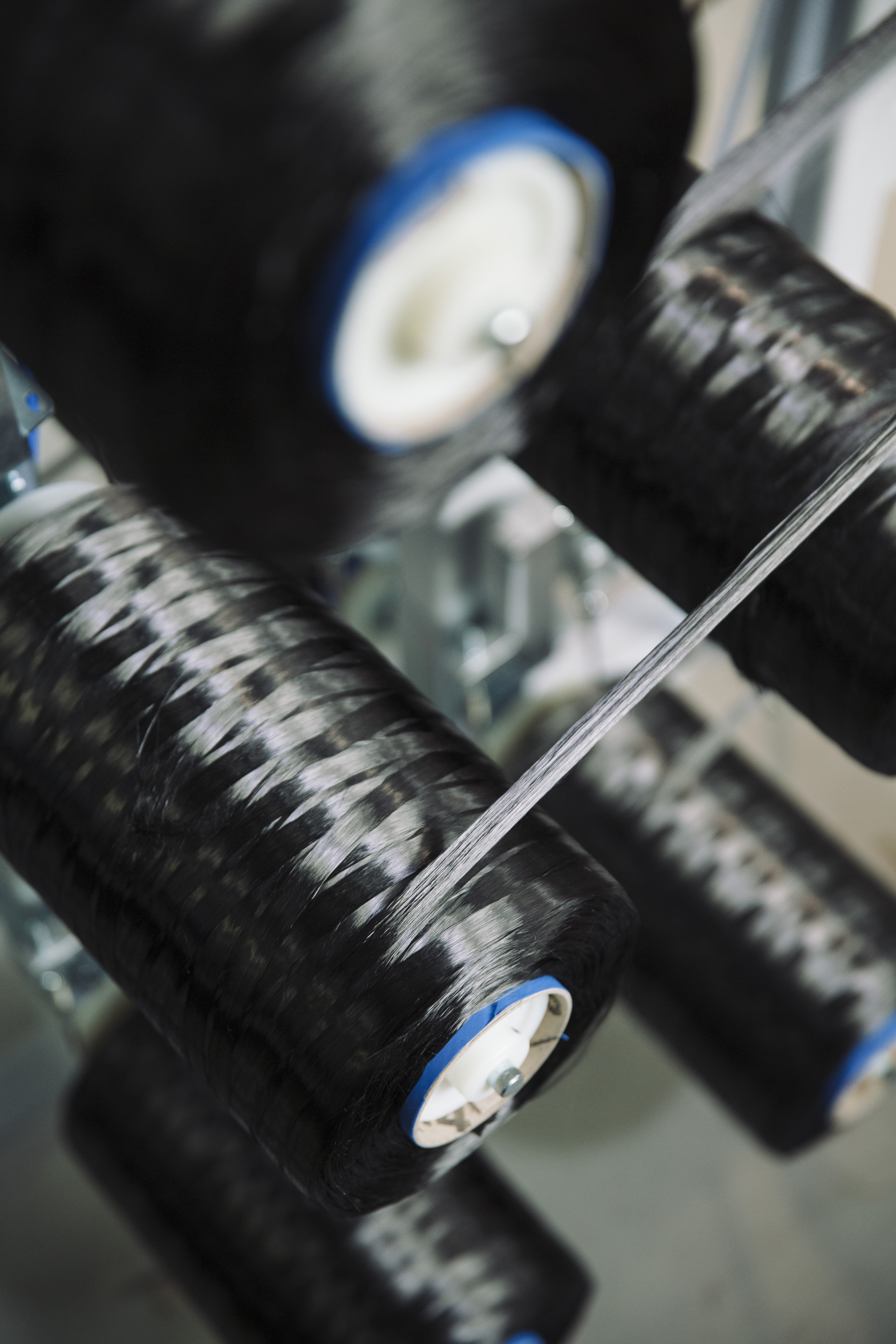

In the production of thermoplastic composites or semi-finished products, the complex and heterogeneous microstructure of the composite material itself as well as its influence during the manufacturing process pose a major challenge, especially for process control and quality assurance. In this context, the end-to-end digitization of the entire production process is essential. Currently, digital twins are only used for individual machines in industrial production, although increases in efficiency can already be seen through targeted machine maintenance and improved production control. However, this is not yet considered as a holistic process, i.e. from the processing of starting materials to the complete production of semi-finished products. This is where our project comes in. With our approach, the complete value chain is mapped digitally and in the real world, so that errors or weak points can be identified immediately. With this we want to find our place "at the edge of technology" in application fields of artificial intelligence.

The Fraunhofer IMWS conducts research in collaboration with other Fraunhofer institutes. Who are the project partners?

We are conducting research with three other Fraunhofer institutes, with the overall coordination lying with the Fraunhofer IMWS. Here, more precisely at the Fraunhofer Pilot Plant Center for Polymer Synthesis and Processing PAZ in Schkopau, we have the manufacturing plant technology available for tape semifinished product production on an industrial scale, as well as the tools for demonstrator structures. The Fraunhofer ICT also supports us with manufacturing equipment as well as tools for tape laying, consolidation and injection molding technology. Relevant material, process and component characteristics (e.g. fiber orientation, pore content, semi-finished product thickness) are to be measured and recorded at Fraunhofer IZFP throughout the entire real value chain. Fraunhofer SCAI will then analyze the measured sensor data, link it to a continuous simulation chain across all process stages, and provide feedback to processes and machines. Through the funding of the Fraunhofer preliminary research, we are also supported by an industrial consortium. The consultants are highly motivated and available for cooperation.