Our clients receive a unique and comprehensive offer for failure analysis and material characterisation. Grouped together in a single centre to save time and costs, run by a committed and service-orientated team, which has excellent knowledge of material-induced problems in microelectronics. In addition there are top level technical facilities - the Fraunhofer IMWS has the most comprehensive equipment for microstructure elucidation within the Fraunhofer community.

Non-destructive defect localisation

- Scanning acoustic microscopy (MHz, GHz)

- Lock-in and pulse-phase thermography

- X-ray analysis and 3D tomography

Target preparation techniques

- Delayering (CMP)

- Metallographic preparation and chemical decapsulation

- Use of laser beams for decapsulation and making transverse sections

- Use of ion beams to make transverse sections and for polishing

- Locally limited mechanical grinding method, preparation from the IC rear

- Cryo ultramicrotome, rotating microtome

Focused ion beam method and electron microscopy

- High-performance FIB system and chem. etching of grooves in Si, integrated IR microscope

- Crossbeam FIB system with EDX and EBSD

- Crossbeam FIB system for the TEM Lift-out method

- ESEM FIB system with cryo transfer

- Low-energy Ar FIB techniques for sample finishing for TEM tests

- Various high-resolution SEM with electrical in-situ contact and EBIC/EBAC

- Analytical SEM with EBSD, EDX, WDX

- Environmental SEM (ESEM) with in-situ investigations and levels

- TEM (200 kV) with ns-EDX and in-situ investigations

- TEM (200 kV) with ns-EDX, EELS, NBD

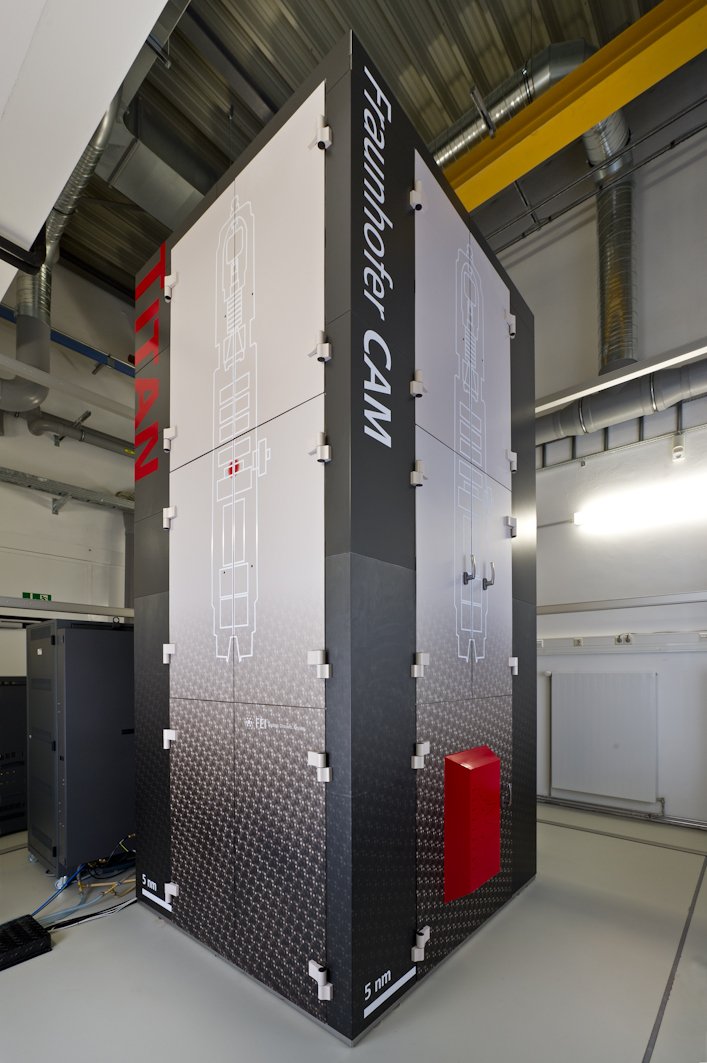

- EF-TEM (60-300 kV) with Cs correction, EDX, EELS, HAADF, STEM

Surface and trace analysis

- Atomic force microscopy (AFM)

- Photoelectron, UV and auger electron spectroscopy (XPS/UPS, AES)

- Time of flight secondary ion mass spectrometry (TOF-SIMS)

- Mass spectrometry with inductive coupled plasma (ICP-MS)

- Contact angle measurements

Crystallography and optical spectrometry

- Micro X-ray diffraction (XRD)

- Electron backscatter diffraction (EBSD)

- IR, light and fluorescent microscropy

- UV/VIS, fluorescence and FTIR spectroscopy

- Micro-Raman spectroscopy

- Electro / photoluminescence

- IR double refraction investigations (for Si components)

Surface topography and deformation

- Mechanical profilometry

- Laser scanning microscopy

- White light interferometry

- Electronic speckle pattern interferometry (ESPI)

- Image correlation systems for the 3D forming analysis

- Wafer bow and thickness fluctuations

Polymer characterisation

- Dynamic differential scanning calorimetry (DSC)

- Dynamic mechanical analysis (DMA)

- Thermogravimetry (TGA) with FTIR

- Thermomechanical analysis (TMA, dilatometry)

- Thermal conductivity analysis (TCA, laser flash)

- Rheometry

Mechanical testing and evaluation

- Static and dynamic material test machines up into the mN load range

- Nanoindentation (T-dependent) and micro hardness test

- Tension and shear tester for microelectronic interconnection technology

- Individualized MEMS, piezo-driven fatigue tests and wafer contact tests

- MEMS analysis including laser vibrometry, stroboscope video microscopy and white light interferometry

- Electrical test station, parameter analysis

- High throughput, thermal shock, humidity and vibration tests