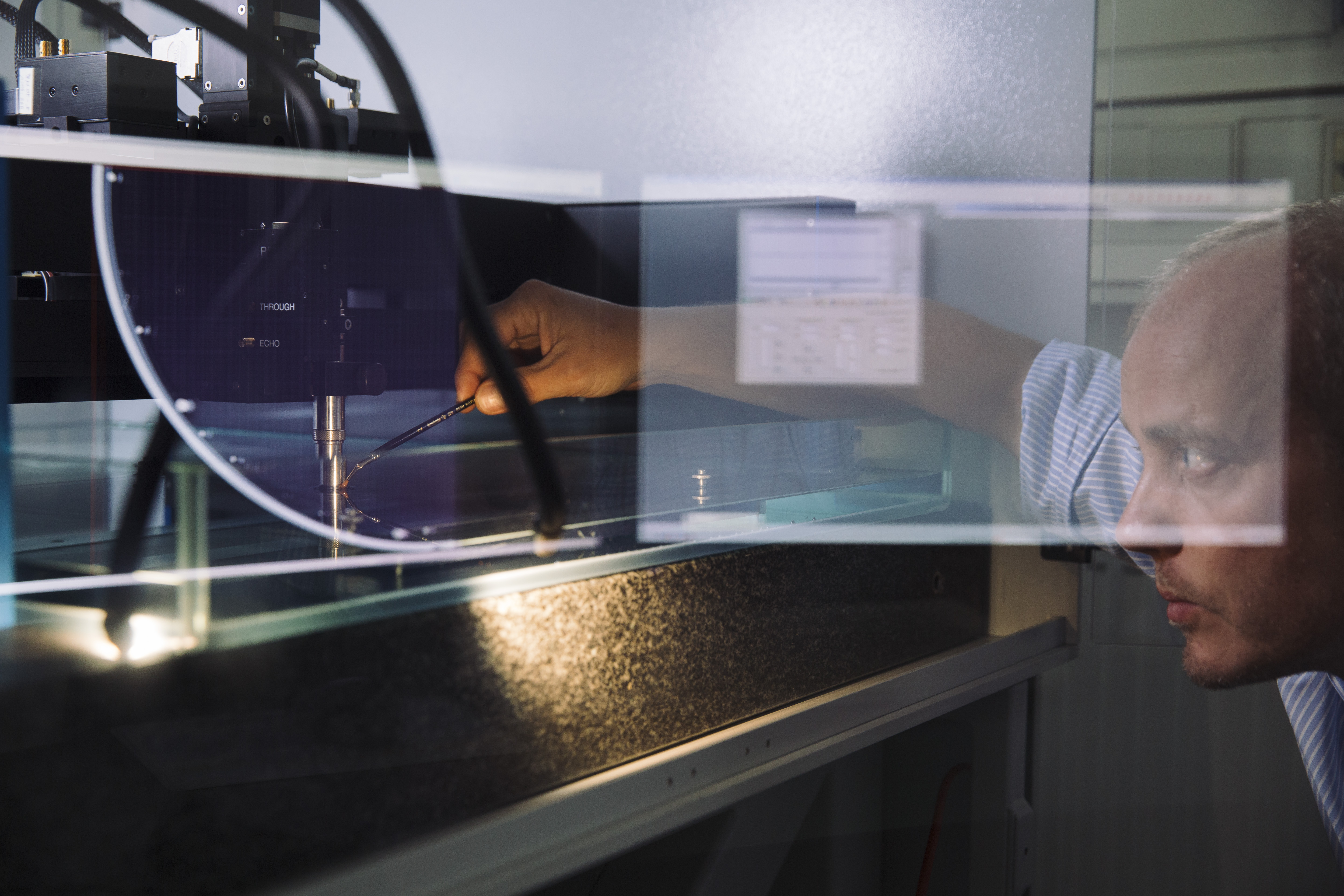

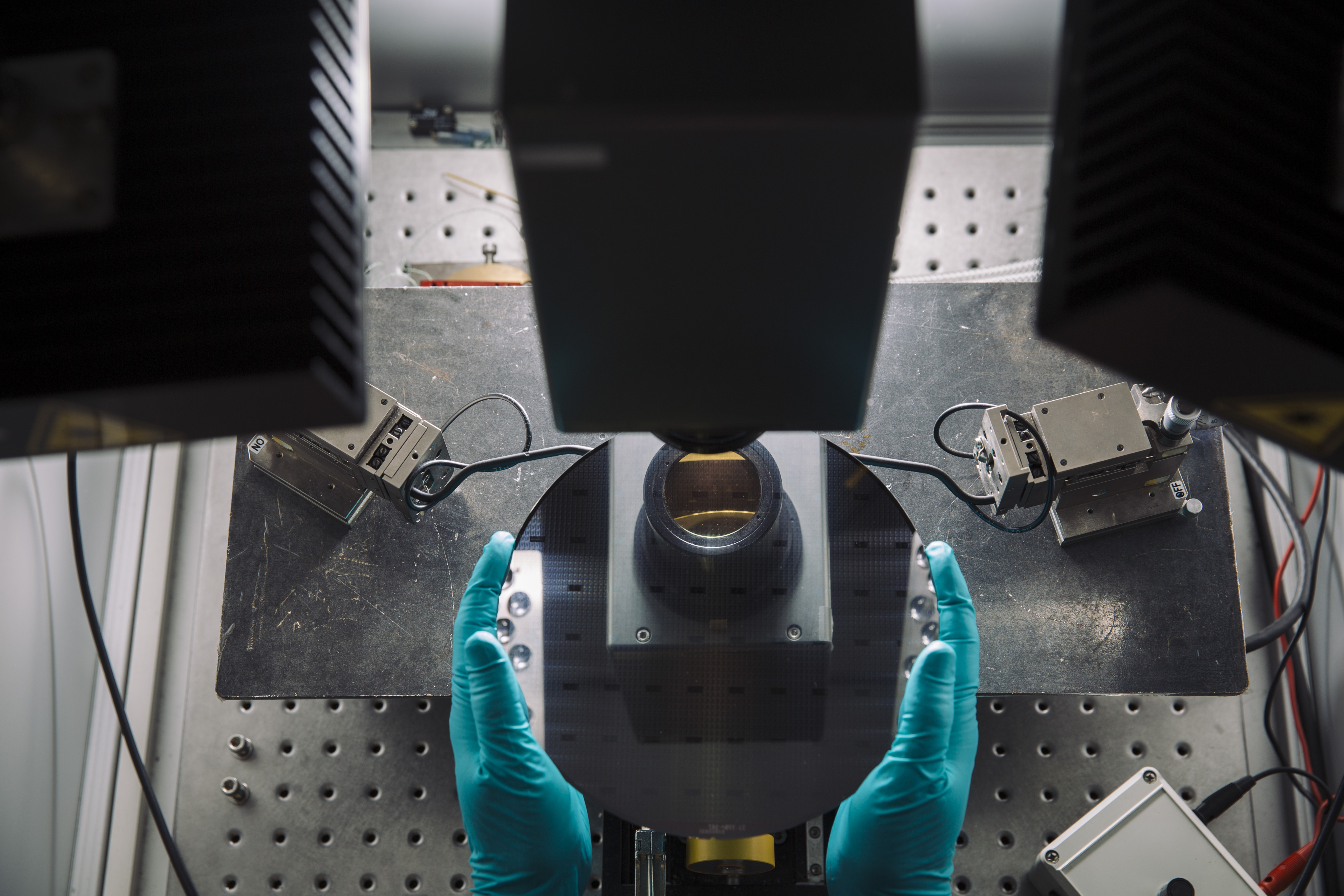

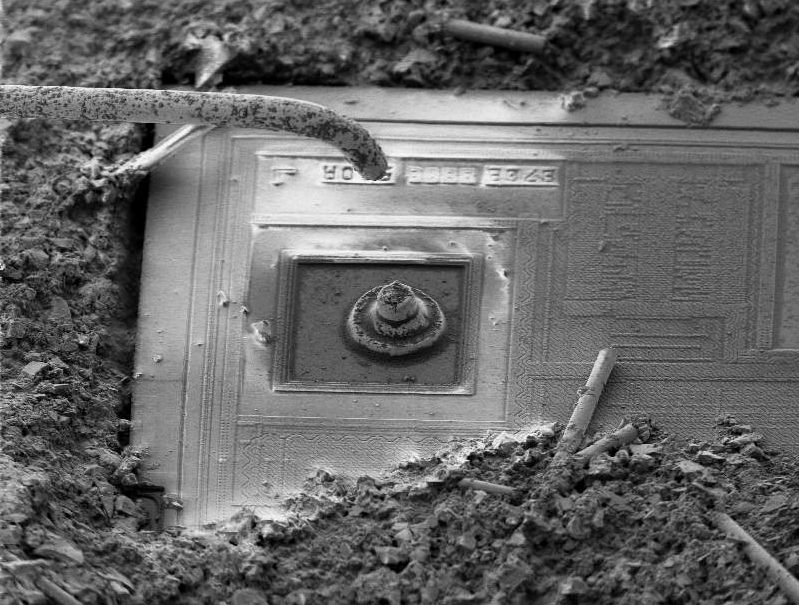

Our Business Unit “Electronic Materials and Components” investigates components, systems and materials of electronics and microsystem engineering, for example integrated semiconductor circuits, sensors, electronic components and assemblies. These are analyzed and tested comprehensively, in order to understand the relationship between technological process and application conditions with microstructure and material properties as well as with the affected functional performance in detail. For the benefit of our costumers, we master complex, powerful methods that include non-destructive analytics, high-resolution methods of electron microscopy and solid-state spectroscopy, surface and trace analysis methods, and mechanical material characterization that includes modeling and numerical simulation.

Major areas of our work are the process characterization on a microstructural level complementing the introduction of innovative technologies as well as the fast and client-focused root cause analysis of faults and of defect formation. The results are incorporated into the clients’ manufacturing processes and thus help to increase the quality and reliability of these systems.

Our clients and partners are mainly from the automotive electronics supplier chain, but also from communications technology, the optics, medical and consumer industry, power electronics for energy and industrial engineering and the segment of equipment suppliers for microstructure diagnostics and testing.

In our research projects with partners from industry or publicly funded projects we investigate electronic components along the entire production chain from wafer to the assembly in the end application.

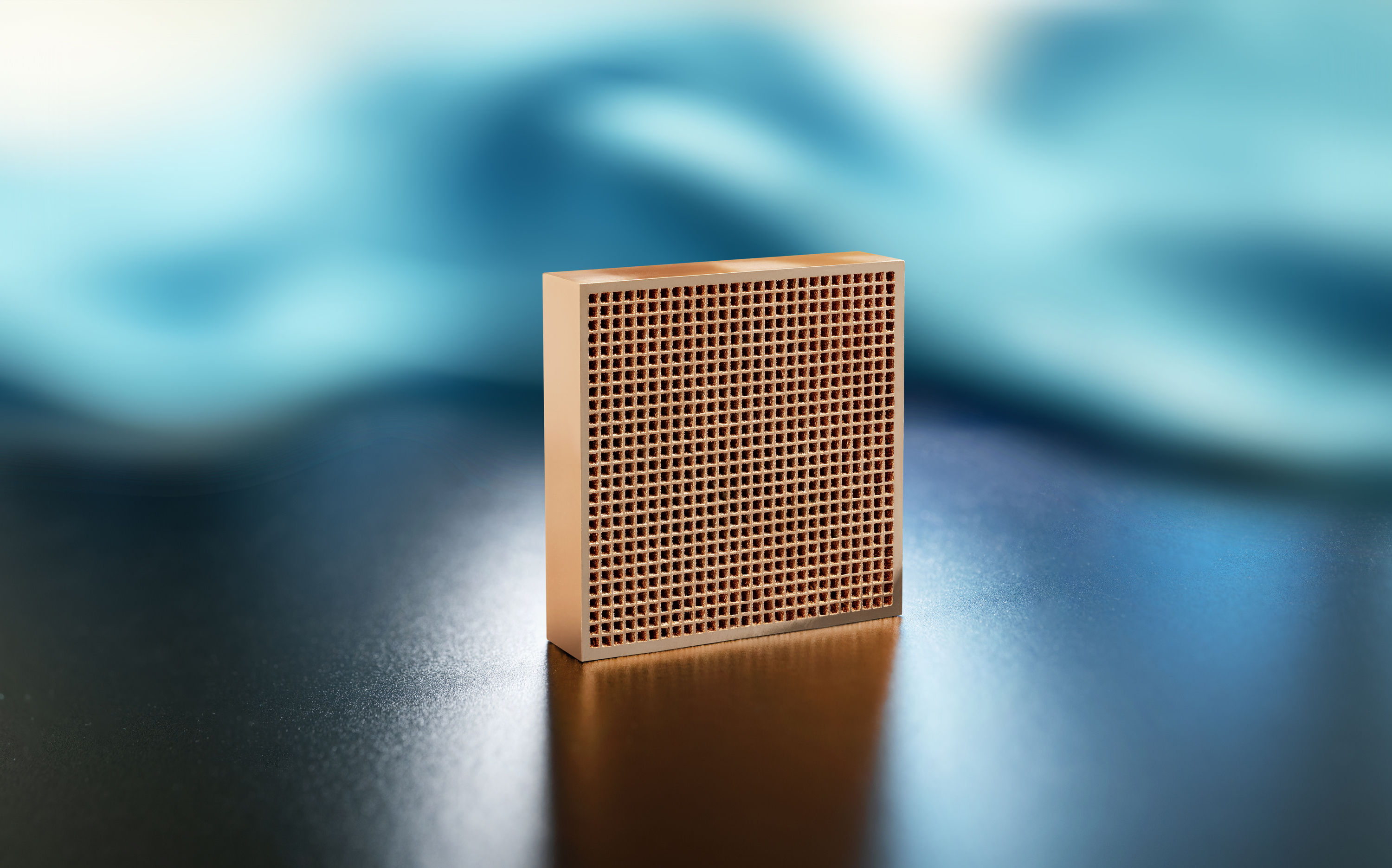

Semiconductor wafers and chips (IC, sensors, power electronics, optoelectronics) of Si technologies, GaN and SiC

Materials and components of packaging and connection technology, power electronics modules

Electronic assemblies and systems, e.g. in automobile applications

Our services are focused on:

Process characterization by means of microstructural analysis in electronics development, especially supporting the introduction of innovative systems engineering and new materials

Complex failure diagnostics for field returns, tracking of causes of faults in qualification or in production

Further development of methods, equipments and procedures for quality control, testing and defect analysis