Safe and lightweight high-pressure tanks for the storage and transport of green hydrogen

Green hydrogen plays a key role for the energy revolution because it can comprise the unifying element between the electricity, mobility, and industrial sectors. For this potential to be revealed, efficient processes for the storage and transportation of green hydrogen are necessary. The four project partners Hexagon Purus GmbH, RayScan Technologies GmbH, the Fraunhofer Institute for Microstructure of Materials and Systems IMWS, and the Fraunhofer Institute for Mechanics of Materials IWM are working together on the development of safe and lightweight high-pressure tanks in which hydrogen can be stored and transported at an operating pressure of up to 1000 bar. This allows for significantly more efficient distribution and the usage of this sustainable source of energy.

The community project is part of the innovation project HYPOS in which more than 100 partners have come together to drive forward the usage of green hydrogen in the chemical industry, refineries, mobility, and energy supply. The starting point for green hydrogen is electricity that is generated from renewable energies and used for electrolysis, from which hydrogen results. At the same time, hydrogen, as an important raw material, is obtained from renewable sources and is no longer based on fossil fuels.

Green hydrogen can be stored in large tanks and transported in pipelines. So that it also reaches consumers in rural areas or at gas stations within the city and can be stored temporarily for short periods of time, in addition, adequate storage and transport tanks are required. Because gaseous hydrogen has a low, volume-specific energy density, high-pressure tanks make for a feasible storage solution: Inside, the hydrogen is highly compressed. In a tank made for 1000 bar, almost 600 times as much hydrogen fits inside than in an uncompressed state and more than double as much in a 350-bar container. Energy is also consumed for compression; however, it’s a significantly smaller amount compared to, for example, the process of liquefying hydrogen and storing it in cooling tanks at temperatures below -250 °C.

Pressure tanks with a capacity of 200-350 bar (sometimes 500 bar) are common for hydrogen transport. The project partners hope to increase this value substantially. The goal is especially safe and lightweight containers that can be used at an operating pressure of up to 1000 bar.

“Higher operating pressure brings with it enormous advantages for the efficient distribution and temporary storage of hydrogen, as well as for high-performance tank systems. To achieve this, a balanced, optimized material and component concept for the pressure tank is necessary”, says Fabian Richter, Development Engineer at Hexagon, who coordinates the project, which will run until November 30th, 2021.

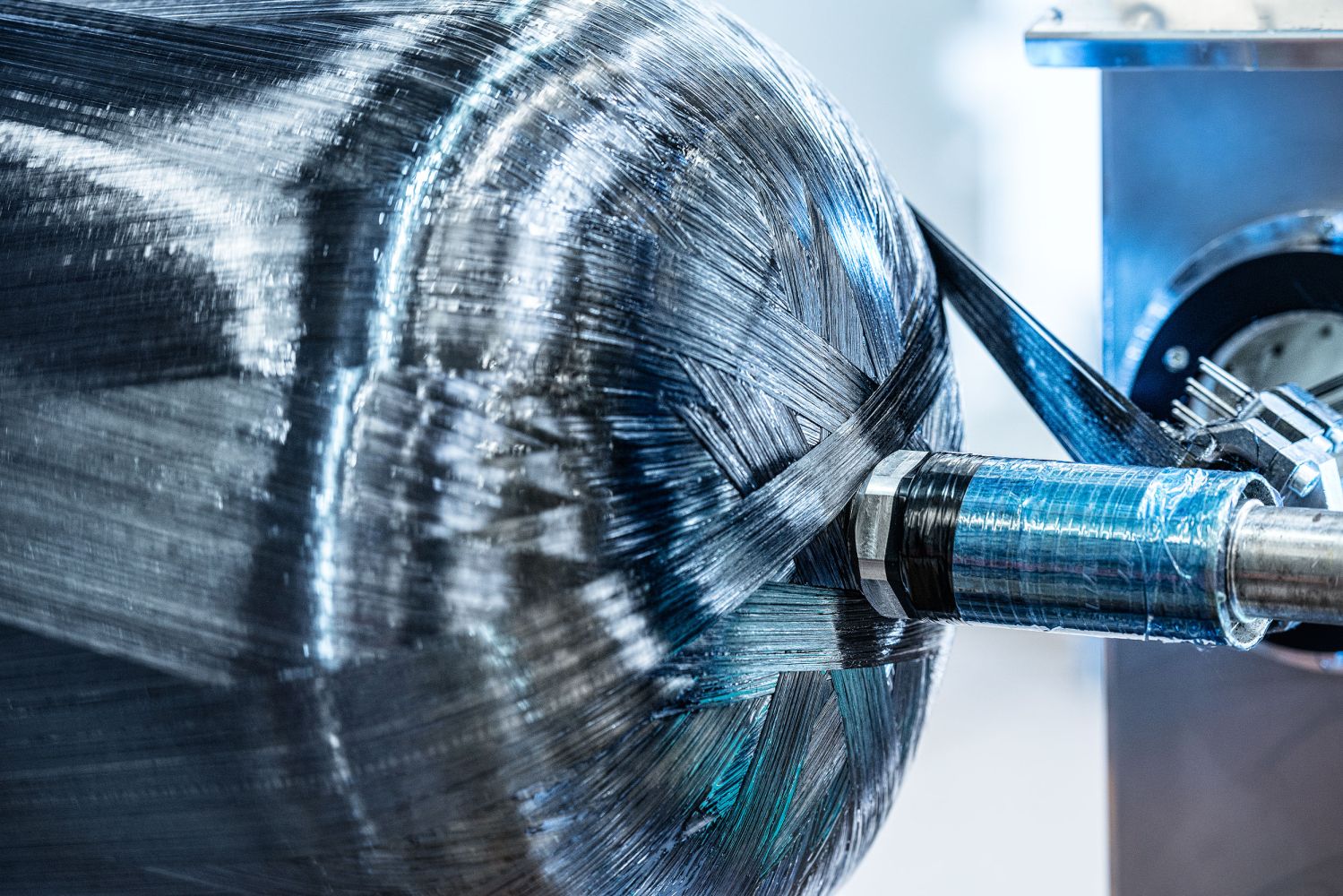

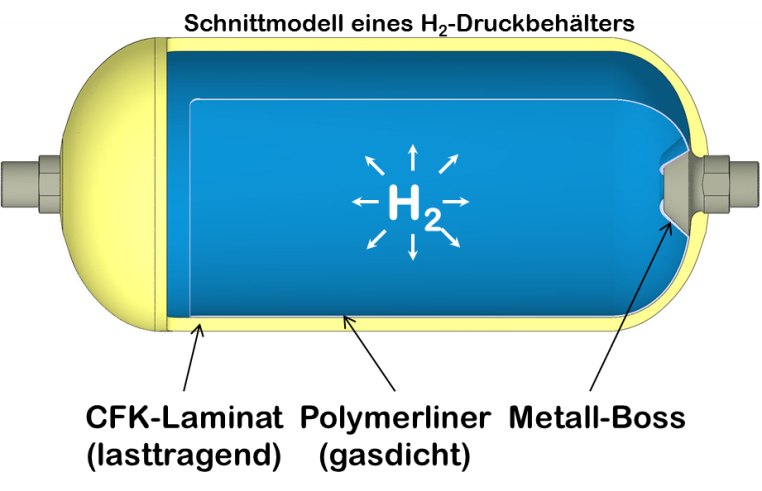

Synthetic hybrid tanks are especially suitable to reach this goal. Such containers are coated with a fiber-reinforced plastic as a weight-bearing structure. Inside is a thermoplastic synthetic liner that ensures gas impermeability. Metal elements are added to the ends of the container as well. “This multi-material character brings with it several challenges. The coating itself is a hybrid bond made of carbon and glass-fiber-reinforced thermoset plastics,” explains Richter.

Several problems like hydrogen embrittlement or corrosion are eliminated because synthetic materials were used for the liner and non-metallic materials. With that said, at operating pressures of up to 1000 bar, there are still several unanswered research questions: How does the laminate made of fiber-reinforced plastic behave when the tank is filled up or emptied? Does the bond between the liner and the coating remain stable, even in the event of extreme temperature fluctuations and other burdens? How does hydrogen interact with the different materials and what kinds of effects does that have on their aging process and lifespan? How can production-related imperfections (like layer thickness tolerances, fiber-angle deviations, pores, dry fibers) and their impacts on the use of the container be evaluated?

To answer these questions, the project partners are researching the scientific bases of the materials. They would also like to produce and comprehensively characterize scaled container model structures, as well as large tank models. Not the least, a suitable testing infrastructure is to be established for the new containers in order to be able to demonstrate operational safety with adapted stress tests.

So that the new high-pressure tanks can prove their performance capability, for example, an improved thermoplastic liner material is to be developed and integrated into the container concept that ensures a low hydrogen permeation rate even with high storage pressures. Based on their understanding of the material, as well as the microstructure of the materials used, the project partners want to develop a novel macroscopic damage material model that can also be used for the reliable forecasting of the component behavior. Numerous, particularly non-destructive test procedures are used that are also to be developed further within the scope of the project. The goal is to come up with concepts for an efficient 3D X-Ray test that allows for 100% quality control during production in the later series manufacturing process of synthetic hybrid pressure tanks.

”With safe and lightweight high-pressure tanks, we can combine the ecological potential of green hydrogen with additional advantages: To transport the same amount of energy, fewer vehicles or fewer trips are required. At the same time, we increase the bandwidth of possible applications – and, last but not least, there are substantial cost benefits for the company,” says Richter.