Expertise in the corrosion behavior of materials, components, and systems

Corrosion is defined in DIN EN ISO 8044 as a process in which a material becomes damaged due to interaction with its environment. Examples of such influencing factors in the environment include moisture, high temperatures, or pollutants. The corrosion process, which often progresses gradually, can lead to substantial impairment of the function of a component or system and even to its failure. Corrosion can occur under mechanical stress as well as when no stress is present. However, corrosion stress and corrosion behavior can be clarified and quantified through measurements specifically designed for individual materials and combinations of materials and by measuring the effects of different media on them. Such tests are a key to efficient reliability analyses.

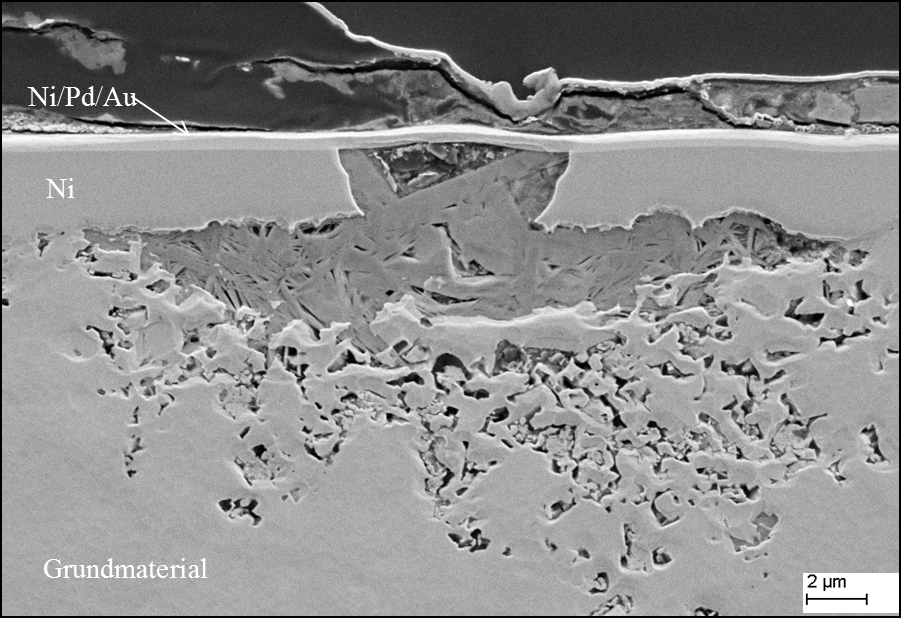

In tests of the quality of microelectronic and power electronic components, and especially of their packaging and connection technology, an understanding of the corrosion behavior of materials plays an increasingly important role. In addition, electrochemical (ionic) migration or ECM is also becoming more and more significant as a fault mechanism. This is due on one hand to the increasing use of of electronic systems in the automobile industry or in renewable energy applications, for example, where the materials and components are exposed to extreme conditions that can facilitate or accelerate corrosive processes. On the other hand, increased miniaturization means components have more surface area but the same volume – which offers corrosive media more potential targets.

At the Fraunhofer IMWS, we have a wide range of corrosion test methods available. With our corrosion test methods, we can analyze electrochemical corrosion and migration processes triggered by the presence of an electrolyte or an electrical field (such as pitting, contact, and crevice corrosion) as well as corrosion caused by purely chemical processes. The experts at the institute in Halle (Saale) have been examining electronic components with respect to their fault mechanisms and causes of failure since 1992. The spectrum of testing and analysis methods ranges from comparative measurements using standard methods and chemical analyses (even for difficult-to-access electronic components like connectors or circuit boards) to the development of materials, for example by chemically modifying the surfaces of contact materials. One focus of the Fraunhofer IMWS is high-resolution physical methods (scanning electron microscopy, energy dispersive X-ray analysis, transmission electron microscopy) that make it possible to detect local damage due to corrosion ranging from wire connections and electrical contacts to the micro- and nanomorphology, for example, as well as enable the clarification of failures. Together with partners, the researchers also develop new methods and devices for testing corrosion.