Corrosion processes play an important role in the reliability of electronic components. A test developed at the Fraunhofer IMWS now enables faster and more efficient testing of the corrosion behavior of new materials and combinations of materials.

Depending on the environmental conditions, e.g. the humidity, temperature, and pollution level, corrosive processes can occur on the materials used in electronic components. These processes are reactions between the material and its environment. They lead to the failure of the electronic components, for example through degradation or crystalline growth on ultra-thin wire connections and contacts. The percentage of failures in applications due to corrosive processes has increased significantly over the last five years. This is due to the progressive miniaturization and widespread use of control electronics, for example in automotive and power electronics. For this reason, the Fraunhofer IMWS researches the corrosion behavior of packaging and component materials used in microelectronics and power electronics in the framework of publicly funded research projects and cooperations with industry.

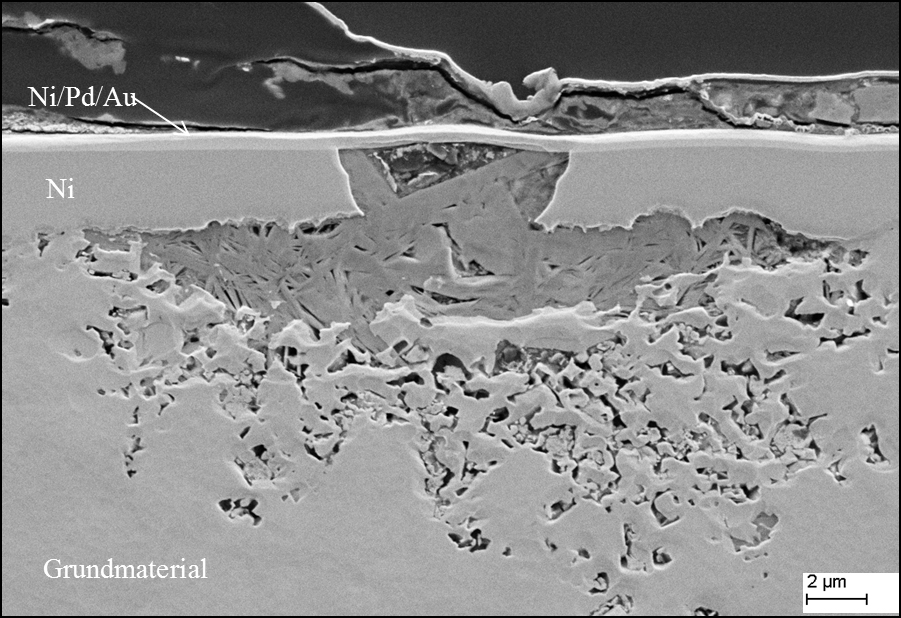

In cooperation with partners from industry, we also develop new contacting materials and test their corrosion stability, among other projects. Previous standard tests for corrosion in gas environments like the 4-component mixed flowing gas test or the salt spray test are complex and take a very long time. That is why the Fraunhofer IMWS developed a test that enables the corrosion behavior of new materials and combinations of materials to be analyzed much faster and more efficiently. Through the use of specially modified liquid electrolytes in electrochemical tests, it is now possible to perform a brief preliminary analysis to quickly recognize the less suitable combinations of materials and exclude them from further analyses. This significantly reduces the number of samples required for technology qualification in the framework of the standard tests. The transferability of the results from the electrochemical test developed at Fraunhofer IMWS to the four-component mixed flowing gas test as well as the salt spray test was verified through comparative microstructural analyses of the local failure mechanisms on relevant electrical contact layer systems such as Bronze-Ni-NiPd-Au and on aluminum materials. The results were also published scientifically.