Fiber-plastic composites based on a biopolymer matrix and continuous natural fiber reinforcement (Bio-NFK) are also set to be used in lightweight structures in the future – i.e., components that can withstand maximum loads and ensure stability despite their low weight. Using the example of a child seat for cars, the Fraunhofer Institute for Microstructure of Materials and Systems IMWS, together with its project partners Evonik Nutrition & Care GmbH, SachsenLeinen GmbH, Chemnitz University of Technology, and EDAG Engineering GmbH, as well as GK Concept GmbH, Britax Römer Kindersicherheit GmbH, Knoten Weimar GmbH, and ID Berlin, are demonstrating the possibilities offered by the newly developed material, technology, and component design concepts for natural fiber-reinforced biopolymers.

Lightweight products from the aircraft and automotive industries often consist of conventional plastics based on petroleum and inorganic fibers (e.g., carbon or glass fiber). They already make a significant contribution to environmental protection, as lighter aircraft and road vehicles consume less fuel. Such solutions become even more sustainable when the polymer matrix itself consists of bio-based raw materials and native plant fibers are used for the reinforcing fibers, for example.

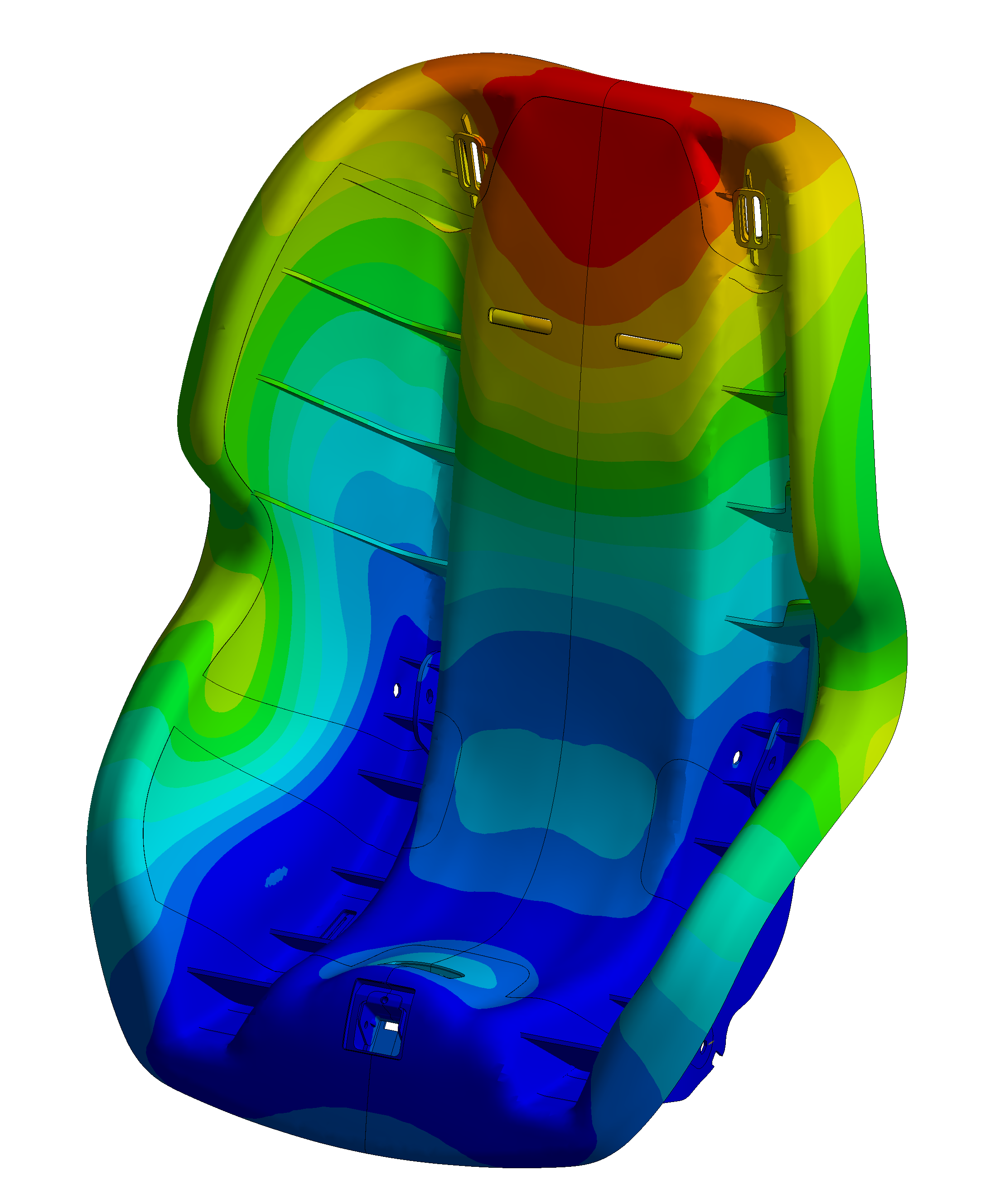

The joint project, which is funded by the Federal Ministry of Food and Agriculture, aims to demonstrate that these bio-based materials can also be used for high-performance applications. The aim is to combine thermoplastic and thermoset-specific material properties in a hybrid component in such a way that they meet high structural and safety requirements. As part of the project, research into material, technology, and design concepts for component applications based on natural fiber-reinforced biopolymers is initially planned on a laboratory scale and will then be transferred to a pilot scale. The aim is to validate these newly developed materials, technologies, and construction methods using a hybrid injection-molded demonstrator in the form of a child seat shell.

To achieve this, various work packages are being carried out in collaboration with the project partners. The first important sub-goal focuses on the research and further development of modified bio-based thermoplastic materials that are combined with natural fibers to form an injection molding compound and an endless fiber-reinforced high-performance composite and must have specific properties. "We want to focus on the use of domestic natural fibers such as bast fibers or cellulose as reinforcing materials and adapt the property profile of the polymer matrix so that it is suitable for high-performance composites and, in addition, is very easy to process," says Ivonne Jahn, subproject manager for "Bio-NFK Semi-Finished Products" at Fraunhofer IMWS. To achieve this, the polymers are modified by electron irradiation after thermoplastic processing in such a way that subsequent cross-linking gives them a thermosetting character and thus improved properties in terms of mechanical strength and heat resistance.

The second key sub-goal focuses on the production of bio-based quasi-endless fiber-reinforced semi-finished products. As customized reinforcement inserts for the targeted hybrid high-performance products, load-bearing and material-efficient laminate structures made of unidirectional single layers, known as bio-UD tapes, are to be used in the components. The UD tape semi-finished products are processed into a laminate; in the process, the fiber orientations of the semi-finished product can be adapted to the subsequent load on the component and the preforms can be constructed close to the final contour with minimal waste.

The third important sub-goal deals with the design and manufacture of safety-relevant hybrid injection-molded components using the example of a prototype demonstrator in the form of a seat shell. Recycling concepts for bio-based lightweight structures are also being researched. The aim is to validate the developed material, technology, recycling, and design concepts as well as their transferability to the industrial production of lightweight applications. "Using the biopolymer demonstrator produced in the hybrid injection molding process, we can make well-founded statements about the structure-property relationships and load limits of bio-NFK components. If all objectives can be successfully implemented, we will be able to achieve significant weight reduction and economical and sustainable production overall thanks to the increased lightweight construction potential and thermoplastic-based lightweight construction. This means that we are developing more sustainable semi-finished products that meet all requirements in terms of subsequent component safety, thereby protecting our environment," explains Dr. Matthias Zscheyge, subproject manager for "Bio-NFK Hybrid Molded Parts" at Fraunhofer IMWS.