Cardiovascular diseases are the leading cause of death worldwide. One of the greatest challenges remains the treatment of small blood vessels: conventional PTFE-based prostheses reach their limits here. The Fraunhofer Institute for Microstructure of Materials and Systems IMWS in Halle (Saale) is taking a new approach with the research project “VasoPRINT”. The goal is to develop a multilayered, biocompatible material system for vascular prostheses, inspired by the extracellular matrix.

To close the existing medical gap in the treatment of small blood vessels, innovative solutions are needed that closely mimic biological structures while being manufactured with technological precision. This is exactly where “VasoPRINT” comes in. The project combines advanced manufacturing technologies such as 3D bioprinting and electrospinning with an intelligent material system modeled on the human extracellular matrix. The aim is to produce patient-specific vascular prostheses that provide safe and long-lasting solutions for vessels with diameters below eight millimeters as well as for larger blood vessels. These prostheses are designed not only to ensure blood transport but also to actively promote tissue integration and reduce complications such as thrombosis or inflammation.

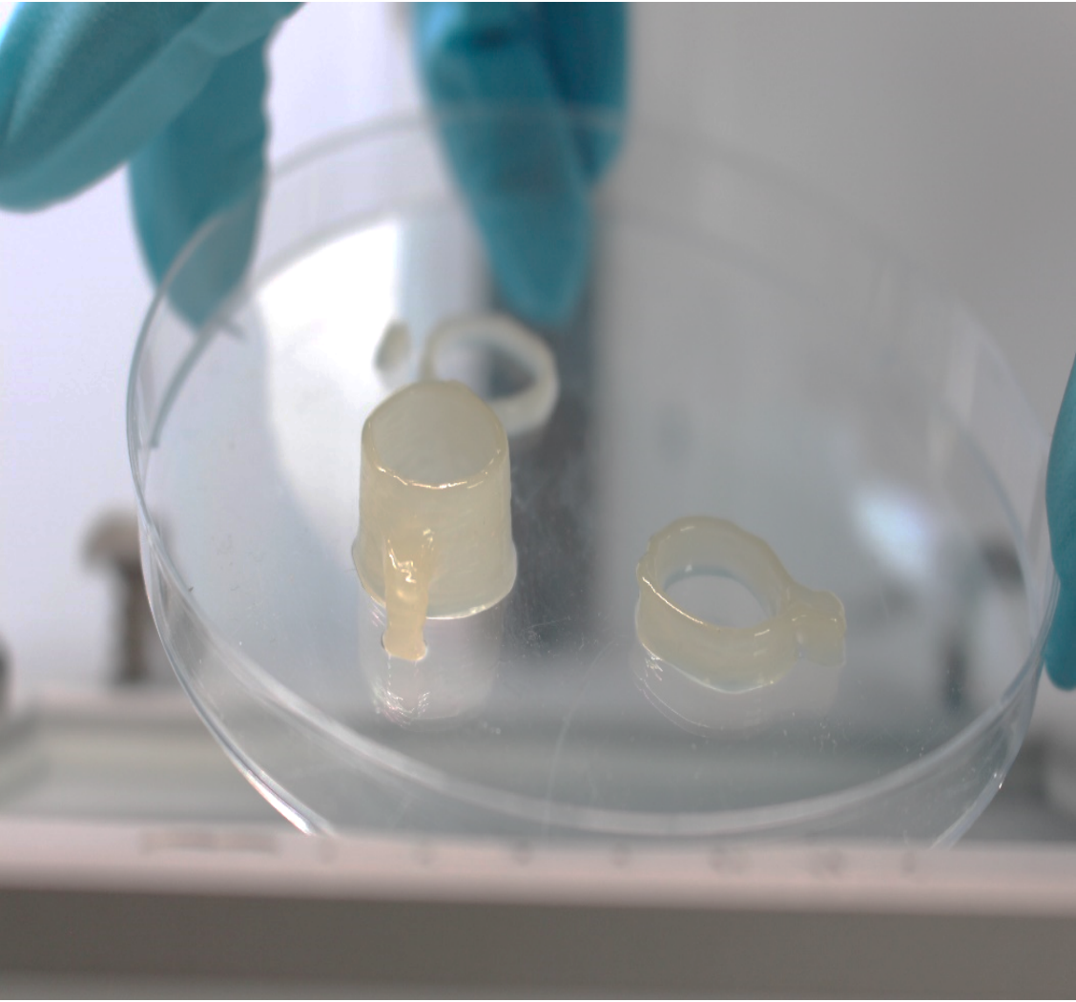

The technical implementation is based on a three-layer structure: a nanofiber material serves as a functional support for cells, a soft gel matrix forms the vessel wall, and an integrated scaffold provides mechanical stability. Only well-established biomaterials are used: elastin gives the system elasticity and tensile strength, while collagen supports cell adhesion and tissue integration. Chitosan and gelatin are incorporated into the electrospun nanofibers to enhance biological functionality. Chitosan has antimicrobial and anti-inflammatory properties and can reduce thrombogenicity (the tendency to form blood clots). Gelatin improves processability and further promotes cell adhesion. This material combination ensures high biocompatibility along with a robust and functionally optimized structure.

Fraunhofer IMWS contributes extensive expertise in the development, functionalization, and characterization of protein-based biomaterials, particularly elastin and collagen. A platform technology for electrospun elastin-based nanofibers is already established and is now being adapted to collagen. The technological core includes a Cellink Bio X bioprinter and a Fluidnatex electrospinning system, which enable precise construction of the different material layers. In addition, Fraunhofer IMWS is developing its own bioreactor to study material compatibility under defined conditions. State-of-the-art analytical equipment, including a laser scanning microscope, a scanning electron microscope, and a texture analyzer, supports the development process.

“In this project, we combine elastin, gelatin, collagen, and chitosan to create an intelligent, multilayer material system. By merging 3D bioprinting with electrospinning, we develop personalized vascular prostheses that offer improved biocompatibility, reduce complications, and can be adapted to the needs of individual patients, particularly for small vessel diameters,” explains Sofia Salazar Silva, project lead at Fraunhofer IMWS.

The innovation lies not only in the material combination but also in the pathway to safe application: the microstructuring is based on already approved biomaterials that are chemically modified (e.g., by methacrylation). This could reduce regulatory hurdles and accelerate clinical implementation.

With “VasoPRINT”, Saxony-Anhalt is paving the way for a groundbreaking medical technology that can fundamentally improve treatment for patients with vascular diseases. By closely linking materials research, biotechnology, and industrial application, the project makes an important contribution to the advancement of personalized medicine — with the goal of producing life-saving implants that are precise, biocompatible, and patient-specific.

(October 27, 2025)