Contact materials and interconnects as key points for the functionality in components and systems

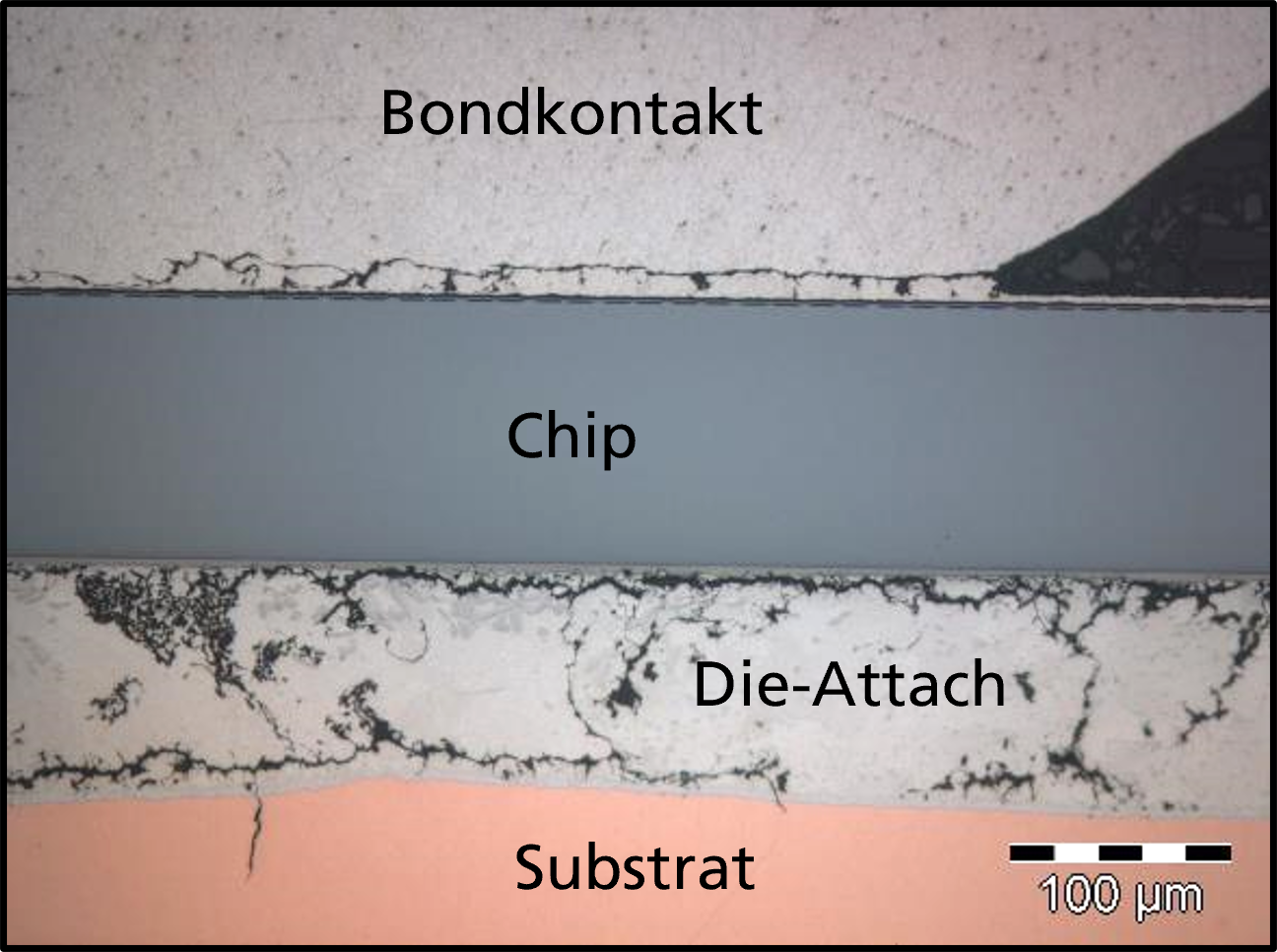

Contact materials and interconnects (e.g. wire bond contacts, soldered, press-fit, adhesive connections) must meet high requirements for efficiency and reliability as they are key points for the functionality of components and systems.

At the same time, mass production, integration density and cost pressure demand high-throughput and robust manufacturing processes, low material usage and cost-efficient composite materials. We support you with our know-how along the entire value chain.