Reliability and service life in operational behavior play a central role

Power electronic devices and modules are becoming increasingly important as they play a significant role in determining the efficiency of generation, conversion, distribution and use of electrical energy in various applications - from mobile phones to hybrid cars and wind turbines. As in other areas of microelectronics, reliability and service life are crucial to the performance of systems. At the same time, very high demands are placed on the quality of components.

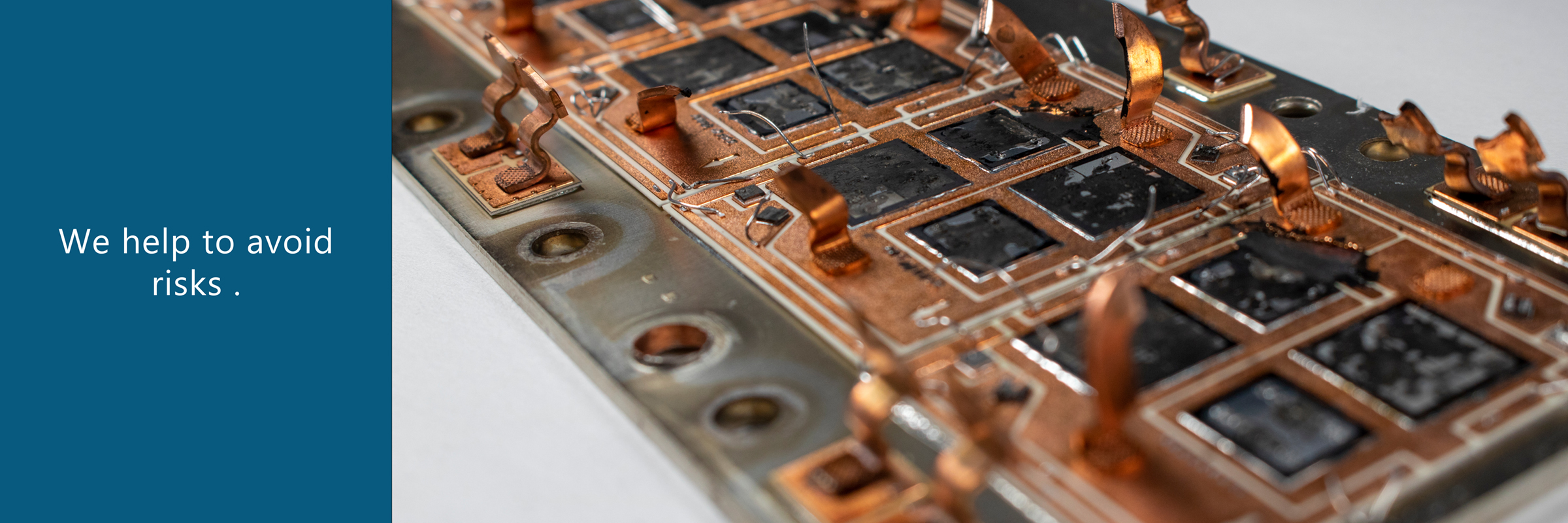

With complex material diagnostics, we research the interrelations between microstructural properties of the materials and components used in power electronic components and assessing their application limits. Our work thus plays a significant role in quality assurance.