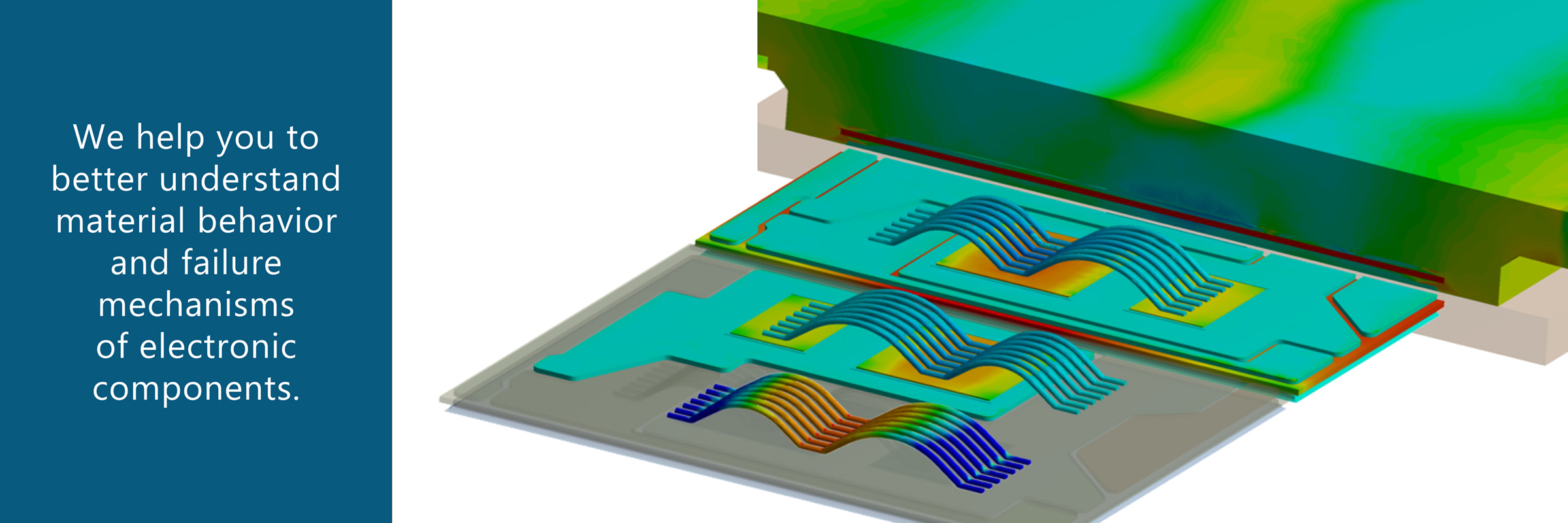

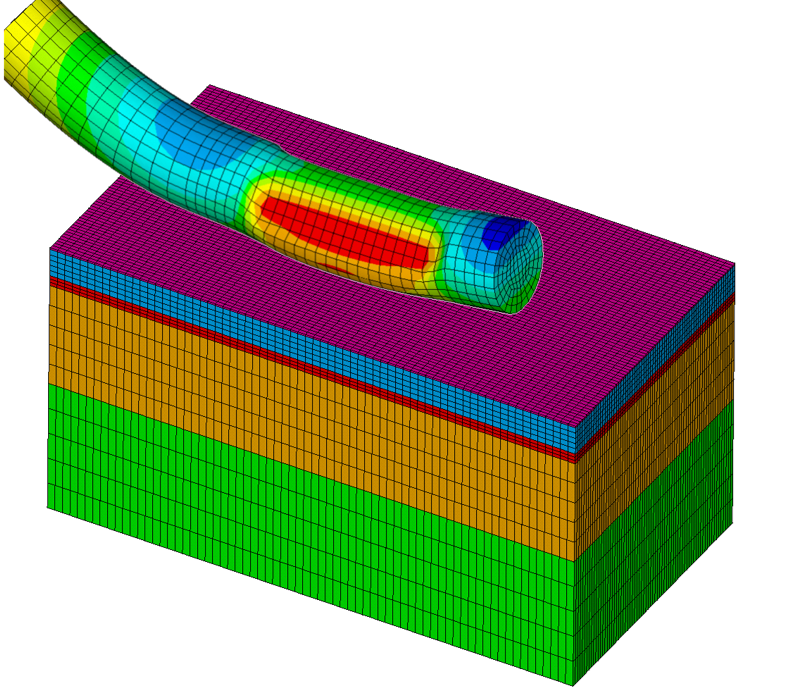

Understanding the complex material and degradation behavior is important for the development process

Renewable energies, electromobility or automated industrial technology pose new challenges for electronic components as they place increasing demands on reliability and operate under more difficult conditions. The right choice of material as well as its characteristics regarding material and fatigue behavior play an essential role in this context.

For this assessment, relevant and load-related material properties must be identified to enable reliable component design. To this end, process- and application-related operating simulations of critical components are included in the development process to better understand potential failure modes.