Luminescent glasses can optimize modern light sources for a variety of applica-tions. Ongoing research work at the Fraunhofer Application Center in Soest is also evaluating new materials such as luminescent glass-ceramics for possible applications. Other initiatives aimed at improving LED technology presented recently by the Fraunhofer team in an article in the specialist magazine High-light include the shaping and the reliability of phosphors.

Over the last 20 years LED technology has become an integral part of the basic configuration of general lighting solutions. The time has now come to further develop it to meet higher demands. The appearance of more intelligent lighting control systems and advanced lighting concepts such as Human Centric Lighting (HCL) means that new requirements must now be met by lighting environments. One possible solution can be found in new phosphors based on luminescent glass. Research on such solutions is currently being conducted at the Fraunhofer Application Center for Inorganic Phosphors in Soest.

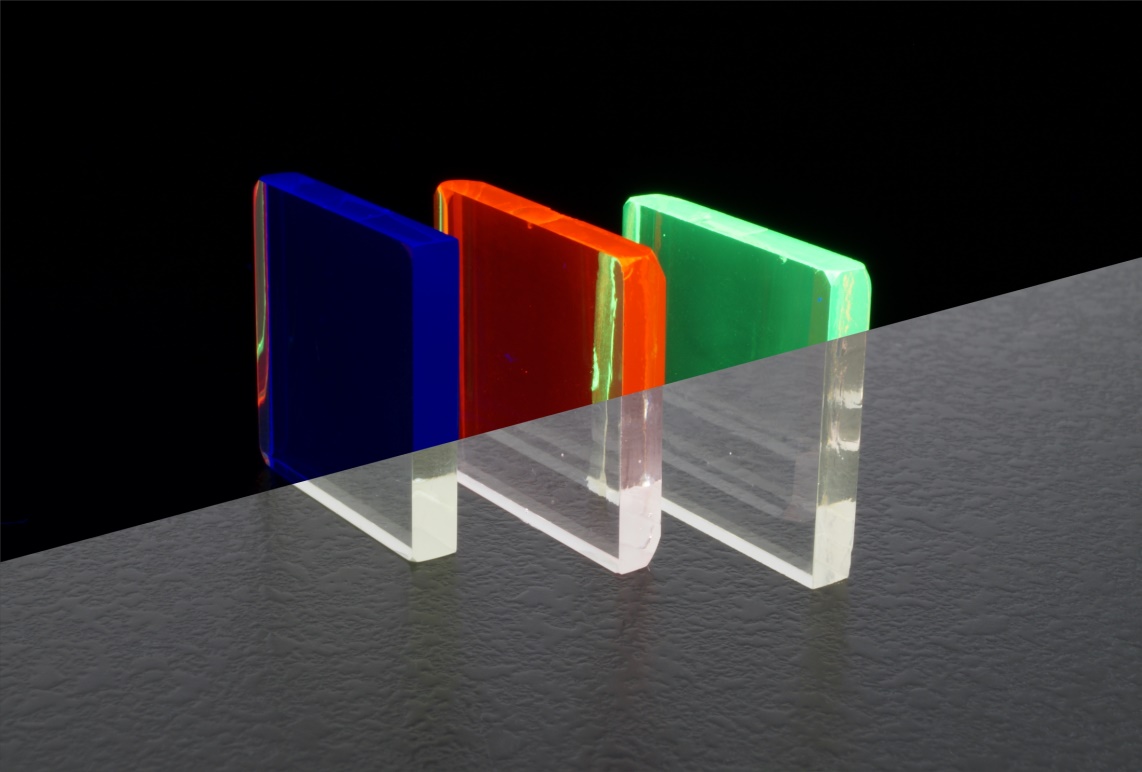

Glass doped with rare earth metal ions can substantially extend the life of white light-emitting diodes and produce a color impression that is stable over time. The glass-based phosphors are characterized by their outstanding material properties and high chemical and thermal stability. When excited by blue light they produce brilliant colors with uniform irradiation in all directions. The glass can also be shaped in any way whatsoever, enabling variety in design. By suitably selecting and combining different rare earth elements it is possible to create a broad spectrum of colors and color temperatures.

An aspect often overlooked in relation to the LED phosphors used in commercially available white light-emitting diodes is the generation of warmth inside the phosphor itself. During the light conversion process energy-rich blue light from the primary LED is displaced to the lower energy range of the spectrum (green, yellow or red). The resulting energy difference is emitted in the form of heat in the phosphor. The thermal output during conversion from blue (450 nm) to yellow (570 nm) light amounts to more than 20 percent of the irradiated light output. Given that more and more applications require higher excitation intensities, the phosphors increasingly heat up giving rise to a phenomenon known as thermal quenching. The luminescent intensity of the phosphor falls, the LED’s color impression changes and is displaced in the direction of the blue, i.e. the “cold-white” range of the spectrum.

Compared to conventional phosphors the phosphors developed at the Fraunhofer AWZ in Soest only display such “quenching” at higher temperatures, explains Dr. Peter Nolte, head of the team Reliability of Phosphors: “We can precisely study the increase in temperature of the phosphor surface in a spatially- and time-resolved manner using an infrared camera. From the heat flow density in the glass, the total heat output can be determined by means of thermographic imaging.”

If required by the application, luminescent glasses can undergo thermal post-treatment to produce luminescent glass-ceramics, whose thermal diffusivity lies above that of conventional yellow phosphors in white light-emitting diodes, Ce:YAG.