Optimizing operations management of photovoltaic parks through digital twin

In their joint “VR4PV” project, the Fraunhofer Center for Silicon Photovoltaics CSP, the Fraunhofer Institute for Factory Operation and Automation IFF, DENKweit GmbH and Dexor Technology GmbH conducted research on how to reduce the operating costs of solar parks and thus generate solar energy more cost-effectively in the future. Using a digital twin, novel measurement methods and machine learning, the research partners succeeded in optimising the operational management of photovoltaic parks.

By 2035, the electricity supply in Germany is to come almost entirely from renewable energies. This was decided by the federal government in April 2022. While in 2022 almost 2.2 million photovoltaic systems installed in Germany with a total of 67.4 gigawatts covered 11.6 % of gross electricity consumption, capacity is to increase six-fold to 400 gigawatts by 2040.

To realize these plans more solar parks have to be built. For solar power to be produced cost-effectively, the operational effectiveness of the parks must be continuously assured, technical failures and the ageing of plants reduced. The monitoring of the plants plays an important role in this context. When building large-scale plants, construction planning data is often entered into the system as initial data - often for financial reasons. Deviations or information altered during construction are only incompletely or incorrectly mapped or not mapped at all resulting in more or less serious deviations between the original plan and the realized building project.

During operation, the lack of reconciliation of planned and actual status data leads to a delayed identification of damage cases and thus to unnecessary technical failures of various system components as well as to a faster ageing of the systems.

This is where the research project "VR4PV" sets in. In cooperation with industry partners, the Fraunhofer CSP from Halle (Saale) and the Fraunhofer IFF from Magdeburg developed a virtual environment and a digital twin of photovoltaic systems for future analysis, inspection and maintenance of photovoltaic parks. A digital twin of an entire solar plant was created combining both the geographical and electrical information of the individual components as well as allowing data and files on these components to be recorded and displayed.

"By means of automated data acquisition and the visualisation of systems, technical problems and yield losses in systems can be detected faster. They form the corner stone

of efficient and reliable commissioning, as well as for the development of operations management and maintenance strategies and associated services based on this," says Dr. Matthias Ebert, group leader "PV Systems and Integration" at the Fraunhofer Center for Silicon Photovoltaics CSP.

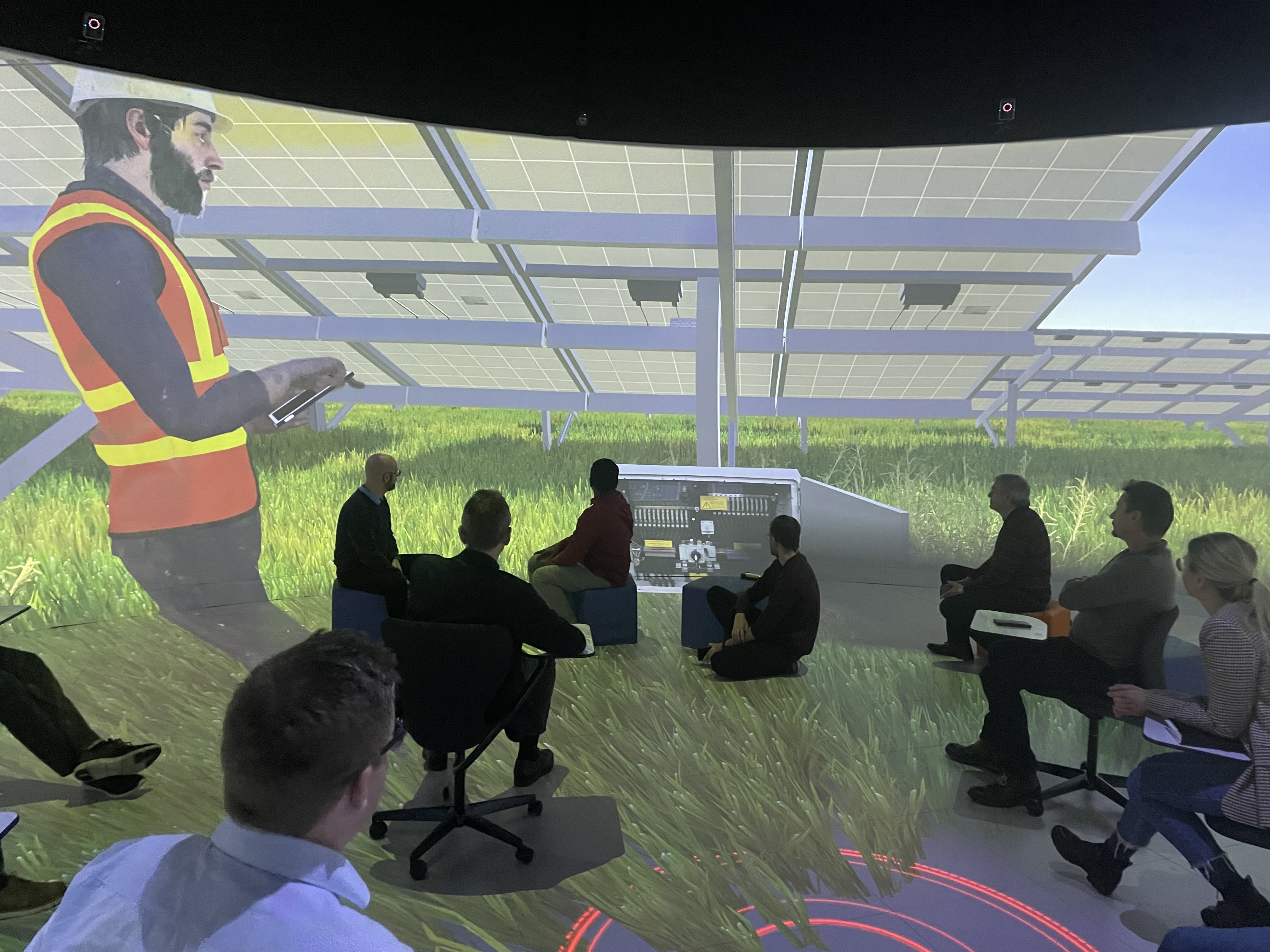

Within the framework of the project suitable imaging methods were used to record the PV systems as a whole, as well as at component level, combining them with the necessary geolocation data. On the basis of deep learning methods, data routines for the automated collection and allocation of plant-relevant variables were developed and applied. Furthermore, researchers developed a data management concept for structuring a database containing the previously acquired and modelled data (health record) based on AutomationML. Using drone and detailed images and AI-based processing, researchers created a digital twin of the PV system under investigation in the form of a 3D model, as a virtual reality application in the Fraunhofer IFF's Elbedome. "We have thus created the prerequisites for a digital twin of PV systems, the benefits of which will now become apparent in its application in operation and during expansions and retrofittings," says Dr. Frank Ryll, Group Manager "Maintenance and Service Management" at the Fraunhofer Institute for Factory Operation and Automation IFF.

Due to the digital structure, the planning status could be compared with the implemented actual status of the PV system. Information was bundled through detailed recording and organisation of digital data, and previously not digitally accessible information documented during construction and maintenance. These measures serve to guarantee a more cost-effective operation and lower energy production costs which in turn reduce the costs of generating electricity from photovoltaics, make systems less susceptible to faults and thus more efficient over a longer period of time.

The project was supported by the state of Saxony-Anhalt as part of the ERDF structural funding. The project ran for one year and formed part of the Regional Innovation Strategy of the State of Saxony-Anhalt 2014-2020 in the field of "Energy, Mechanical and Plant Engineering, Resource Efficiency".