Recovery technologies for the reuse of solar modules

The recycling of components from end-of-life solar modules is an important approach to the sustainable use of resources. This allows certain components of solar modules to be reused or converted into new products. The recently launched joint project "RETRIEVE" aims to make this possible: When recycling solar module components, the goal is to improve the material quality so that it meets the current requirements for reintegration into the photovoltaic value chain. The Fraunhofer Center for Silicon Photovoltaics CSP is contributing its expertise in material analysis and process optimization to the project, which will run until March 2027.

The recycling of solar modules is an important aspect of sustainability in the solar industry. Solar modules contain various materials, including silicon, glass, metals and plastics, which can be recycled to conserve resources and reduce waste. The joint project "RETRIEVE" addresses this issue and aims to contribute to Europe's independence in supply with raw materials. The project partners want to recover valuable resources for photovoltaic modules manufactured in Europe from the predicted influx of obsolete modules and thus simultaneously promote the growth of the European photovoltaic recycling industry.

The approach pursued in "RETRIEVE" aims to reduce dependence on primary raw materials through the circular use of resources. Innovative and flexible recovery technologies are to be developed for each component of silicon-based photovoltaic modules. The aim is to maintain the specifications while reducing the environmental impact of the recycling processes. Important steps here include glass recycling according to current standards, the purification of production waste and end-of-life silicon, the recovery of silver and heavy metals and the development of ways to reuse or recycle plastic through carbon capture in the most valuable way possible.

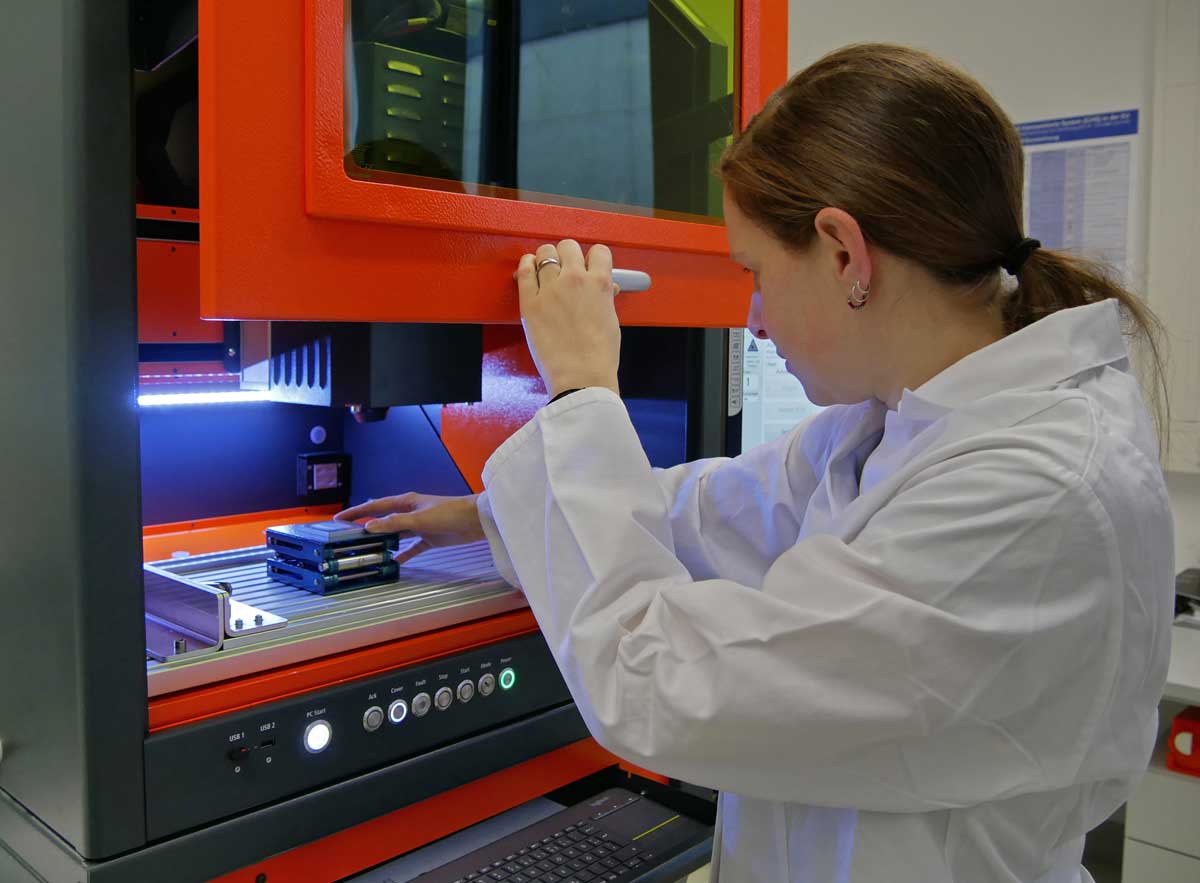

The Fraunhofer CSP is involved in all key process steps of material recovery and recycling, particularly of glass, silicon and metals. The state-of-the-art equipment for material analysis and characterization is used for this purpose, including Inductively Coupled Plasma - Mass Spectrometry ICP-MS, an analytical method for inorganic element analysis, and Laser Induced Breakdown Spectroscopy (LIBS), which enables in-line analysis of element contents. "We also support process optimization within the various purification and further processing steps and investigate material-specific pyrolytic polymer degradation mechanisms," says Dr. Sylke Meyer, Group Manager "Material Analysis" at Fraunhofer CSP.