Lightweight vehicle structures with integrated electronic components for electric cars

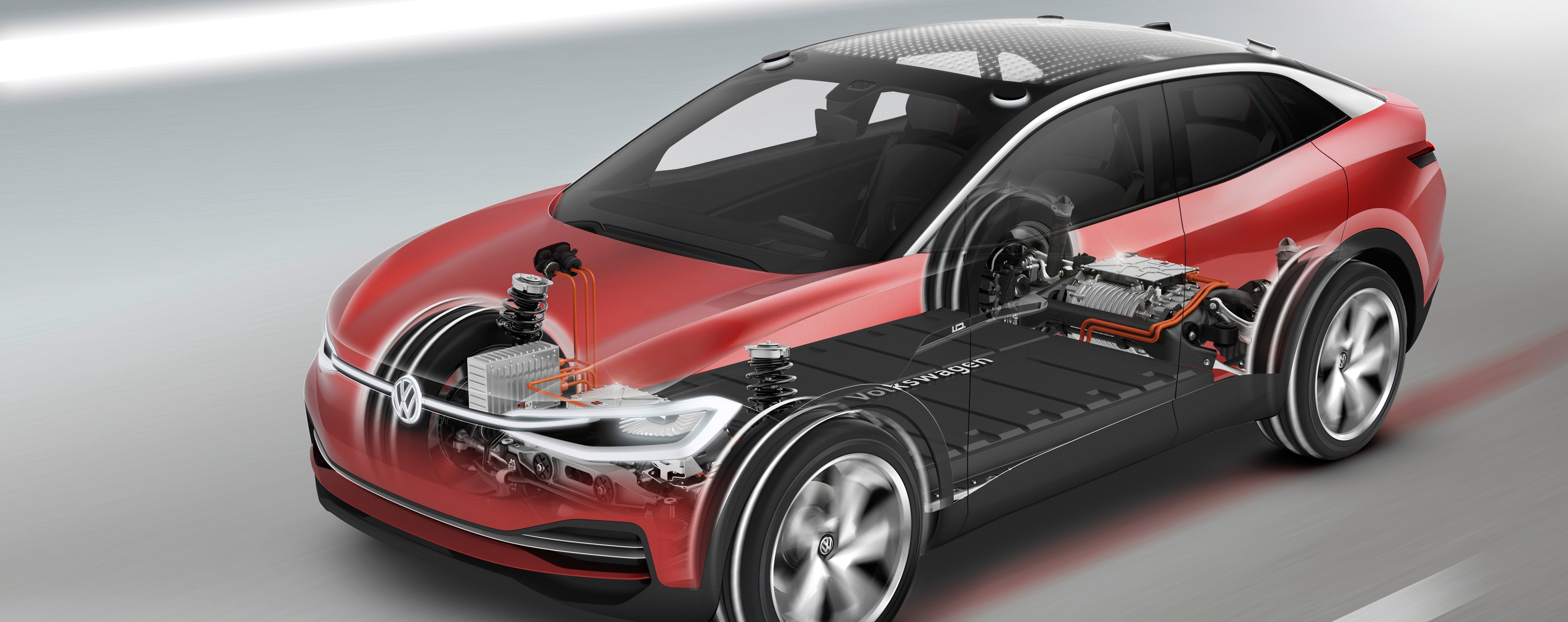

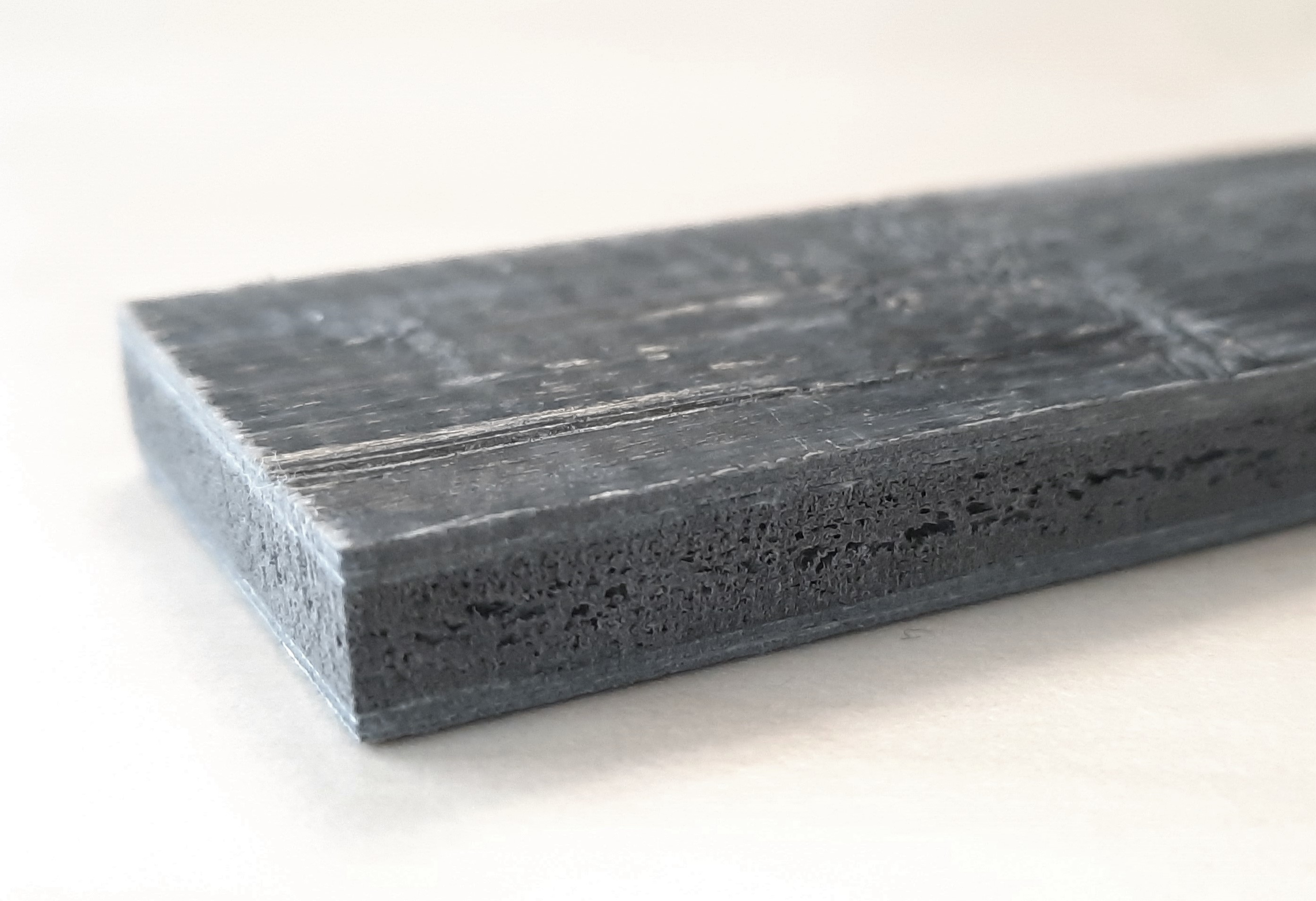

The Fraunhofer IMWS is joining forces with eleven other partners in the interdisciplinary project “InThElekt”. The consortium is conducting research on the manufacturing of innovative lightweight vehicle structures with integrated electronic components for e-vehicles. Using thermoplastic composite sandwich technology and innovative cooling concepts based on novel potting materials, the aim is to reduce vehicle weight and fuel consumption while integrating functions and increasing component reliability.

Just as with a combustion engine vehicle, weight and fuel consumption play a key role in the driving performance of an electric car. Structural vehicle components in thermoplastic FRP sandwich lightweight design can ensure the lowest possible vehicle weight thus reducing energy consumption and increasing the driving range. However, the design of such polymer lightweight structures presents challenges for the connected electronic components. For the support structures based on thermoplastic FRP sandwich technology have a lower thermal conductivity than conventional metal support structures, which can better divert the heat generated by electronic devices. Since this could also have a negative impact on the reliability of the electronic devices, concepts must be found to cool electronic components and optimize thermal conductivity.

In a joint interdisciplinary project, twelve partners, including the Fraunhofer IMWS, are conducting research on an efficient technology for the large-scale production of integral structural vehicle components based on thermoplastic sandwich composites with adapted electronic components. The focus is placed on the interaction of innovative plastics lightweight technology and novel technologies for the integration of electronic components in future e-vehicles. As part of this interdisciplinary project, researchers also concentrate on developing novel potting materials for electronics, thermal management, and interface concepts. Ultimately, research results are tested and validated using a selected e-vehicle assembly group of the Volkswagen AG.

The overall goal of the project is to significantly reduce the global warming potential based on the materials, technologies and construction methods used. Driving performance is to be improved significantly by reducing vehicle weight. The CO2 balance is to be reduced by increasing the recyclability of components as well as by reducing manufacturing and operating costs. Novel heat dissipation concepts and optimized potting compounds should also be able to create highly thermally conductive thermal transitions and thus increase the reliability of electronic systems.

"Future e-cars require interdisciplinary approaches to develop vehicle systems that are as resource-efficient as possible. In particular, the interfaces between modern plastic-based lightweight structures and electronic systems play an important role. We have dealt with the topic of electromobility for a good 20 years. We will draw on our experience to further develop the results of the research project with a view to transferring the technology to large-scale production and applying it to other structural and crash-relevant components," says Dipl.-Ing. Matthias Biegerl, coordinator of the joint project at ElringKlinger AG.

"The Fraunhofer IMWS is involved in both subprojects with its two business units "Electronic Materials and Components" and "Polymer Applications”. The interdisciplinary project approach allows us to fully exploit the range of our competencies in the aforementioned areas so that a concept with the required application readiness is available at the end of the project," says Dr.-Ing. Ralf Schlimper, Head of the group "Evaluation of Fiber Composite Systems" at the Fraunhofer IMWS.

"Plastic-based lightweight structures require new electronic system designs with optimized thermal conductivity and cooling. This requires detailed analyses of the relationship between technological manufacturing processes and operational conditions, the microstructural and material properties as well as the functional properties dependent thereupon. The excellent technical equipment of the Fraunhofer IMWS provides the best basis for this," says Sandy Klengel, Head of the group "Assessment of Electronic System Integration" and Deputy head of the business unit " Electronic Materials and Components " at the Fraunhofer IMWS.

The project forms part of the "New Vehicle and System Technologies" program funded by the German Federal Ministry of Economics and Climate Protection and will run for three years. A total of eight partners and four associated partners from industry and science are participating in the project. The partners include: Berliner Nanotest und Design GmbH, ElringKlinger AG, EDAG Engineering GmbH, Engel Austria GmbH (associated), Fraunhofer IMWS, Hübers Verfahrenstechnik (associated), NetCo Professional Services GmbH, Robert Bosch GmbH (associated), SimpaTec Engineering GmbH, Symate GmbH, Chemnitz University of Technology and Volkwagen AG (associated). Network coordinator for the project is ElringKlinger AG.

The project is divided into three subprojects, with the partners participating according to their competencies.

Subproject 1: Thermoplastic sandwich structural components

ElringKlinger AG, EDAG Engineering GmbH, Engel Austria GmbH, Fraunhofer IMWS, NetCo Professional Services, SimpaTec Engineering GmbH, Symate GmbH, VW AG

Subproject 2: Adapted electronic components

Berliner Nanotest und Design GmbH, Fraunhofer IMWS, Technische Universität Chemnitz und als assoziierte Partner Hübers Verfahrenstechnik sowie Robert Bosch GmbH

Subproject 3: Demonstrator structure with adapted E-component

ElringKlinger AG, EDAG Engineering GmbH, Engel Austria GmbH, Fraunhofer IMWS, NetCo Professional Services GmbH, Robert Bosch GmbH, SimpaTec Engineering GmbH, VW AG